- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

review

£349.99

VERDICT:

If you want your flat-mount disc brakes to run true, and to do it yourself, this pro-level tool is a must

Weight:

0g

Contact:

At road.cc every product is thoroughly tested for as long as it takes to get a proper insight into how well it works. Our reviewers are experienced cyclists that we trust to be objective. While we strive to ensure that opinions expressed are backed up by facts, reviews are by their nature an informed opinion, not a definitive verdict. We don't intentionally try to break anything (except locks) but we do try to look for weak points in any design. The overall score is not just an average of the other scores: it reflects both a product's function and value – with value determined by how a product compares with items of similar spec, quality, and price.

What the road.cc scores meanGood scores are more common than bad, because fortunately good products are more common than bad.

- Exceptional

- Excellent

- Very Good

- Good

- Quite good

- Average

- Not so good

- Poor

- Bad

- Appalling

The Park Tool DT-5.2 Disc Brake Mount Facing Set is £350 worth of guaranteed disc brake alignment. And it's as future-proof as the industry gets.

No one knows just how many disc-braked road bikes will be sold this year, but it's safe to say disc brakes are here to stay. The technology is now at the tipping point of full hydraulic systems appearing on decent bikes at Cycle To Work scheme prices, and Shimano has just announced its Sora R3000 groupset with flat-mount disc brakes and thru-axles. The all-weather, consistent braking future is clearly discs.

> Find your nearest dealer here

With migration to ever-cheaper price points comes the inevitable challenges of quality control, as the requirement for high precision meets the need to keep costs low and fabrication fast. When you are talking about rotor-pad clearances of fractions of a millimetre, getting the calliper centred and square onto the rotor is critical to avoid noise and premature pad wear as one part of the pad contacts the spinning rotor before the other.

Since the introduction of disc brakes to mountain biking 20 years ago, the two standards for bolting callipers to frames have been post mount and international standard (IS). In 2014 Shimano made its flat mount system freely available to all manufacturers, allowing a much cleaner, closer look and, critically, to be able to fit the rear calliper close inside the rear triangle.

The braking forces that callipers have to absorb and transmit through the frame are what engineers call 'very large'. Frames are reinforced around calliper mounting areas, with metal inserts set into alloy and carbon frames and forks for bolts to thread into. If these threaded inserts are not perfectly square or if they have layers of paint or carbon obscuring them then the calliper will never sit squarely in relation to the rotor.

In disc brake systems there are seven areas of possible misalignment or unwanted movement. All seven interfaces need to be either secure, aligned or both in order for your braking system to be quiet, efficient and powerful.

Hub, rotor and calliper design and fabrication now deliver high levels of consistent accuracy even at low price points, leaving mount alignment and preparation ('facing') as the final frontier of braking performance. This is where the Park Tool DT-5.2 comes into the picture.

At the time of writing the DT-5.2 is the only tool able to face flat mounts with their limited rear triangle clearance. At £350 RRP, it's probably the most expensive tool you'll ever buy, unless you get into frame building. Bike shops will charge you about £35 to face your mounts, so if you only plan on buying a few disc-braked bikes in your life this isn't a sensible use of cake funds. But if, like me, you have five cyclists in your house and a reasonably regular turnover of bikes as needs change and legs grow, the DT-5.2 might be a sensible investment. There are also the beers to be earned doing work on friends' bikes...

How it works

The instructions for the DT-5.2 run to 18 diagrams and this video.

I ended up printing and laminating the instructions for reference – there's a definite process to follow, and if you miss a step you could end up chopping away at a mount needlessly, possibly rendering the frame or fork useless.

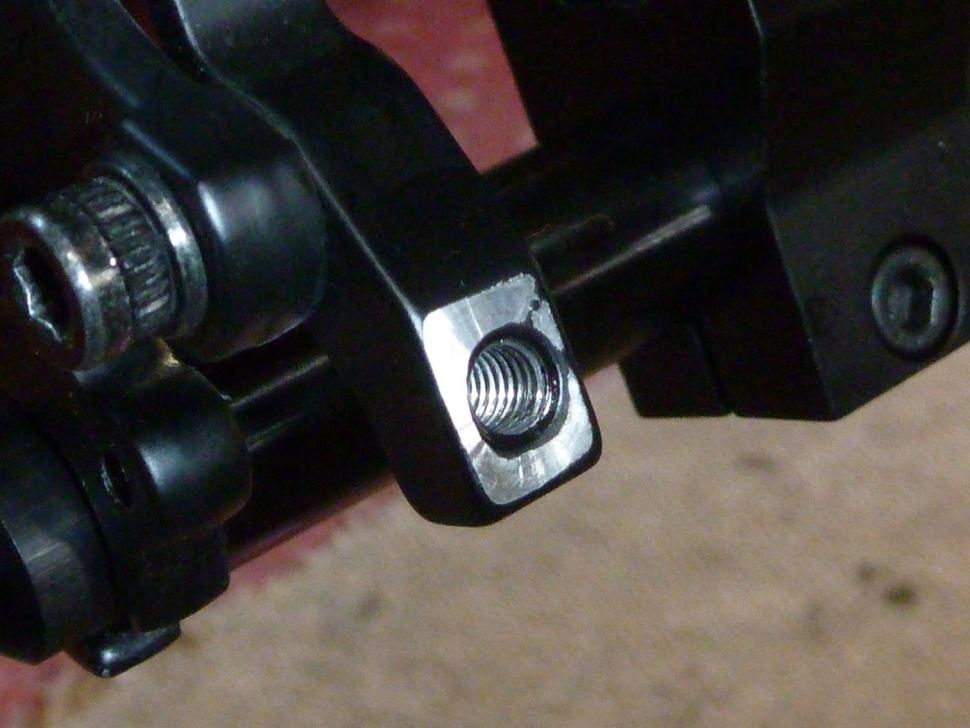

There's a critical setup needed for doing flat mount fork facing, where a unique bolt needs swapping and special inserts need popping into the existing holes to measure the setup before cutting. 'Parallelism' is critical to a clean, accurate cut – you want both mounts to be perfectly parallel to each other and square to the axle on which your hub and rotor will spin.

Face off

My first foray into the world of mount alignment was on a Kona Roadhouse with Shimano's BR-505 hydraulic callipers. The front calliper was so out of alignment that the rotor rubbed incessantly, and on removing the calliper it was obvious there was a layer of paint and carbon over the upper mount that was skewing the calliper.

The process of setting up the cutting head is best left to watching the video. Suffice to say, the facing process worked. After removing what turned out to be 0.49mm of paint and a smidge of carbon (NB: see Darren Bancroft's comments, below) to expose the mount fully, the calliper sat flat and the rotor ran true.

Moving on to other bikes with IS, post or flat mounts, with 12mm, 15mm or traditional QR axles, the process was easily replicated – again, following the instructions carefully. There's a measurement collar that acts as a reference between cuts, to make sure you end up with both mounts at the same level. Often the difference is fractions of a millimetre, so attention to detail is key.

Across all the bikes I worked on there were notable improvements in calliper-rotor alignment. The DT-5.2 is proper engineering-grade stuff, and the results show it.

Splash out?

So should you rush out and spend £350 on a DT-5.2? That depends on how many bikes you own, how often you change them, if they have disc brakes and how much beer you think you can earn from friends/club mates in return for tuning their setups. Yes, manufacturers should deliver bikes fit for purpose, and in a perfect world the DT-5.2 shouldn't have to exist. In the real world it's critical to ensure as good an alignment as possible, and on a used bike there's often no comeback.

There are much cheaper mount facing tools available, but none of them does flat mounts, or supports the multitude of different axle 'standards'. If you're sold on disc brakes and enjoy a good fettle, the DT-5.2 should be on your radar, especially if flat mounts become the standard, which I think is likely.

• Footnote: if you own one of the earlier Park Tool disc mount facing sets, the £150 DT-5UK kit will upgrade your existing system to support the various new thru-axle standards. If/when yet more 'standards' emerge, it's a pretty safe bet Park will issue further upgrade kits to keep your investment useful.

Ask the experts

I contacted Darren Bancroft from repair firm Carbon Bike Technics for his take on facing carbon forks.

He advised brake mounts should be faced on jigs in the factory – and that there's no reason to put any material, paint, carbon, whatever, on top of a faced surface.

Where you have a protruding insert, Darren suggests using a fine file to remove any paint or carbon overspill on the top by working around the insert corners at a 45-degree angle, then remove the contaminant with a sharp blade prior to facing. Of course, if the insert is flush with the surface this will be a problem, and Darren doesn't recommend using a facing tool to tidy up a carbon fork where you are cutting carbon fibres themselves – you should just send it back to the retailer.

What if it's a secondhand bike? Darren acknowledges this is a decidedly grey area.

I also contacted Sean Lally, owner and instructor at Cycle Systems Academy, for another professional take on the whole disc-mount-facing meme:

Mike: How important is calliper alignment?

Sean: If you want your brakes to not rub, and to work optimally, this is critical.

MS: What sort of clearance are we talking for a disc calliper? Do they differ between low and high-end? Mechanical vs. hydro?

SL: 1mm can make the difference with any brake, hydro or rim.

Mike Jenner (fellow Cycle Systems instructor) adds: "There is a difference between low and high and mechanical and hydro. Hydro will be much easier to set up. There are generally issues with mechanical one-sided disc brakes as the rotor is pressed onto the static pad and this can be difficult to set up.'

MS: Should all frames be faced before install?

SL: Yes, but this is usually done by the manufacturer or importer. Even a cheap Ribble alloy frame will be full faced and reamed upon delivery, and that is under £100 retail.

MS: Do you trust manufacturers to get it right?

SL: As above, most of the time, yes. However, one of the problems with outsourcing to overseas factories can be quality control. You may come across a particular manufacturer or batch which is poorly faced, or not faced at all.

MS: If you think the calliper isn't faced correctly, should the shop/manufacturer remedy it for free?

SL: The shop should check this and face the disc mounts as part of the PDI (Pre Delivery Inspection). Obviously, a quality independent store is more likely to do this than a large chain.

MS: Should all custom builds be checked/faced first?

SL: Again, I would expect the manufacturer to do this, but yes, you do want to ensure this task HAS been performed.

MS: If you are dealing with issues, should facing be the very first step?

SL: Not at all, disc brakes have many simple adjustments, from calliper alignment to centralising the pistons or using the correct spacers. However, properly faced mounts are the bedrock of the calliper location and cannot be compensated for elsewhere.

MS: Any other thoughts?

SL: One interesting issue was your own, where the carbon protruded over the flat mount, preventing the alloy mount from being faced without damaging the carbon. Carbon fibre cannot be faced as, of course, this will weaken the structure of the frame or the fork and could lead to catastrophic failure. As with all facing and reaming tools, practise using this tool on an old frame first. Do not go straight to your best bike and just start grinding away, as you can't glue the metal back on. Once it's gone, it's gone.

Verdict

If you want your flat-mount disc brakes to run true, and to do it yourself, this pro-level tool is a must

road.cc test report

Make and model: Park Tool DT5.2 Disc Brake Mount Facing Set

Size tested: n/a

Tell us what the product is for, and who it's aimed at. What do the manufacturers say about it? How does that compare to your own feelings about it?

Park Tool says:

Faces any IS Mount, Post Mount, or new Shimano® Flat Mount, including low clearance chainstay mounts

Telescoping axle adaptors allow use with any configuration of open or thru-axle dropouts and dropout widths (including Boost 110, Boost 148 and all fat bike axles)

Includes two facing cutters:

IS Mounts

Post and Flat Mounts

Includes storage case

Tell us some more about the technical aspects of the product?

It does every current standard of brake mount and axle on the market.

Rate the product for quality of construction:

10/10

Serious engineering on show here – very tight tolerances, as would be expected.

Rate the product for performance:

10/10

It does an excellent job.

Rate the product for durability:

9/10

Everything seems very well made.

Rate the product for value:

6/10

If you have need to set up discs regularly, this will pay for itself in time and workshop costs.

Tell us how the product performed overall when used for its designed purpose

Very well indeed for such a complex item covering so many use cases.

Tell us what you particularly liked about the product

The end result – it's very satisfying to see smooth, parallel faces.

Tell us what you particularly disliked about the product

The price – yikes!

Did you enjoy using the product? Yes

Would you consider buying the product? Yes

Would you recommend the product to a friend? Yes

Use this box to explain your score

If your use case fits, the DT-5.2 will save you time, money and ensure perfect braking performance for ever more.

About the tester

Age: 43

I usually ride: Merida Ride 5000 Disc My best bike is:

I've been riding for: Over 20 years I ride: A few times a week I would class myself as: Expert

I regularly do the following types of riding: club rides, general fitness riding, fixed/singlespeed, mountain biking and Dutch bike pootling

Living in the Highlands, Mike is constantly finding innovative and usually cold/wet ways to accelerate the degradation of cycling kit. At his happiest in a warm workshop holding an anodised tool of high repute, Mike's been taking bikes apart and (mostly) putting them back together for forty years. With a day job in global IT (he's not completely sure what that means either) and having run a boutique cycle service business on the side for a decade, bikes are his escape into the practical and life-changing for his customers.

Latest Comments

- David9694 1 hour 3 min ago

I usually just screen shot the picture, re-upload and that solves it. I also find some pictures saved from news sites won't upload and screen...

- David9694 1 hour 9 min ago

Spare a thought for Phil from Fowey whose cut-through is closed; if only there was an alternative. He's even done a video. ...

- chrisonabike 1 hour 15 min ago

Even in NL (with excellent wide cycle infra, some of which actually started as motor scooter paths) they're having second thoughts about "motor...

- chrisonabike 1 hour 21 min ago

It should be possible to check the figures out for NL where the have (civil) presumed liability, no?...

- brooksby 1 hour 31 min ago

Yup - they ought to return it as defective

- chrisonabike 1 hour 33 min ago

Dunno about Ireland, but in the UK we already have "causing death by dangerous driving" - brought in IIRC because the courts wouldn't charge or...

- Capt Sisko 1 hour 37 min ago

SIXTY QUID - They're having a laugh.

- chrisonabike 1 hour 55 min ago

Exactly - "war on the motorist" when it's probably never been better (in terms of cost, safety, sometimes convenience although the presence of ever...

- HollisJ 2 hours 51 min ago

Make fun of people who want to spend their money however they wish (much as I think this is a twatty thing to do), but are you seriously making a...

Add new comment

1 comments

Hmmm, could have used this a few times... might get one.