- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

dt swiss PR 1400 Dicut OXiC1.jpg

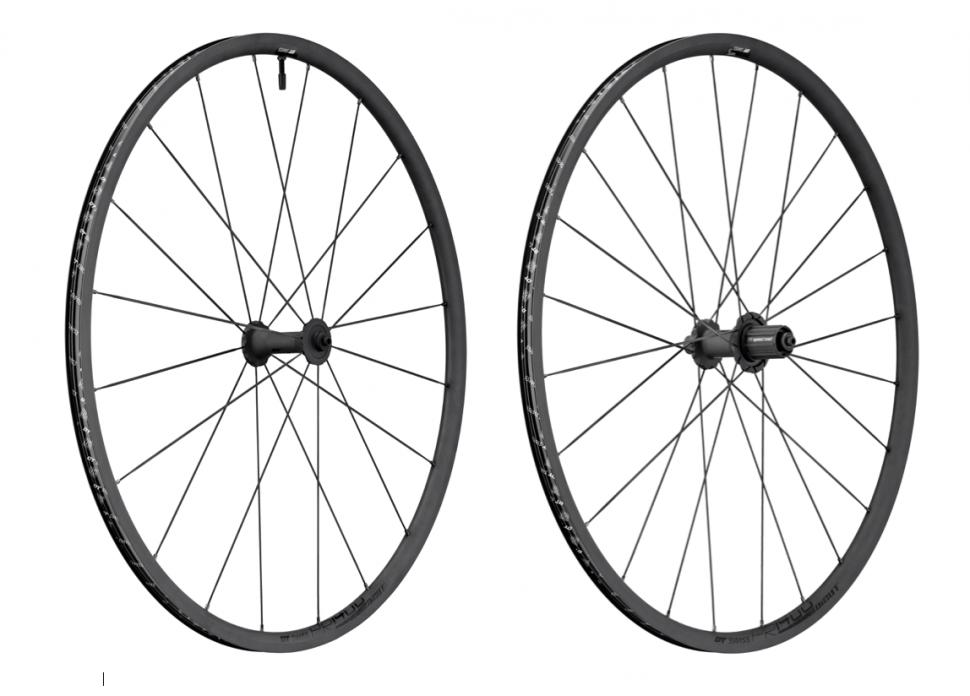

dt swiss PR 1400 Dicut OXiC1.jpgDT Swiss launches the ‘pinnacle of aluminium wheels’ with new PR 1400 Dicut OXiC

‘The pinnacle of aluminium wheels’ is the bold claim DT Swiss is making for its brand new PR 1400 Dicut OXiC wheels.

They weigh 1,435g and the tubeless compatible rim is the first to be treated with the company’s OXiC ceramic coating, which it claims to provide improved braking performance in all conditions and won’t wear out over the normal lifespan of a wheelset.

This OXiC coating, which DT Swiss says is environmentally friendly, is electrochemically applied to the rim surface. Ceramic rim technology isn’t anything new, Mavic used to sell the excellent Open Pro Ceramic which had many fans due to its durability.

DT Swiss its treatment is able to deform with the rim so there’s no chance of the coating become detached from the rim if it's dented following an impact, as could happen with Mavic’s ceramic rims. The finish also won’t fade in the sun.

- Buyer's Guide to road bike wheels, plus 17 of the best

Here’s a more detailed explanation of the process from DT Swiss:

“The ceramic layer is achieved similarly to anodizing, by submerging the rim in an electrolyte solution while applying an electrical tension between the rim as one electrode and the container as the other. The decisive difference between anodizing and OXiC lies in the millions of plasma discharges that occur between the electrolyte and the rim, applying high temperature and pressure on the developing oxide layer. Due to that, the developing oxide layer melts, flows and solidifies again. During this process the amorphous (not aligned) structure of the oxide converts to a crystalline (aligned) one. This is why OXiC is so hard and wear resistant.”

So now you know.

The rims measure 18mm internally and 21.5mm externally, with a 21mm depth. They’re laced to DT Swiss Dicut hubs with 240s internals and a 36t ratchet system in the freehub, for quick engagement. DT aero comp spokes are used in each wheel, 20 radially laced in the front and 24 in a 2-cross pattern in the rear wheel.

They’re tubeless compatible, which will please fans of tubeless technology, and supplied with a MilKit tubeless kit.

- The pros and cons of carbon fibre wheels

At 1,435g - 635g for the front and 800g for the rear - the wheels are certainly light, but the caveat is the 110kg rider weight limit that DT Swiss has slapped on them.

Finally, they cost £799.98 for the pair and should be available very soon. We’ve got a pair coming to the office to test so we can put them through their paces. More at www.dtswiss.com

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- Rome73 36 min 33 sec ago

that “commuters simply do not need a bike worth more than £1,000”....

- muhasib 5 hours 17 min ago

"Clunie, who was stopped at the lights at the time of the crash,"...

- mikeclarke 7 hours 54 min ago

Sheffield has an appalling road safety record, in particular child deaths caused by cars is above average. A campaign to increase the number of...

- Miller 8 hours 58 min ago

I'm reading this as the komoot founder cashing out? Tough on the staff who'll get a redundancy notice and not a payout.

- Rendel Harris 9 hours 25 min ago

You can pick them up for £129 at Cyclestore now with free postage.

- David9694 11 hours 56 min ago

I certainly don't put every story about every fatal crash I encounter, this pair just got me curious, like why are 90 year olds still driving and...

- Vo2Maxi 12 hours 29 min ago

Over 25 years ago now, I was on the Ideal Travel winter training camp in Majorca....

- chaos 12 hours 37 min ago

Great news for titanium and steel owners like me. My metal rim bikes roll on. Sadly, my venture into carbon territory is a different story. Anyway,...

- Sredlums 13 hours 20 min ago

I honestly can not yet get my head around how this thing is supposed to work. What I do know is that it does not have the chain on each side,...

Add new comment

15 comments

Get a room, you two....

The Dura-Ace C24 is a much better deal, even lighter and alot cheaper. Although these look alot more nice (and I have the C24's).

Looking at the rim profile and the rest of the components, this is almost identical to the DT Swiss DiCut 21 (or RR440 rims laced onto 240 hubs) but with an added coating.

It'd be nice therefore if the forthcoming review would contain either a lab test or a road comparison with the DiCut 21 to ascertain the effectiveness and longevity of the coating.

Looking at the rim profile and the rest of the components, this is almost identical to the DT Swiss DiCut 21 (or RR440 rims laced onto 240 hubs) but with an added coating.

It'd be nice therefore if the forthcoming review would contain either a lab test or a road comparison with the DiCut 21.

DT swiss RR21 db ordered.

Yeah, with disc brake, no one cares the coating any more.

Why not choose cheaper RR21 db?

Yeah, because anodised coating and ceramic coating are exactly the same. Good one

But hey, if you can wear off ceramic coating after one ride then perhaps you can privode us all with the very technical data as to how you managed this by the way of a very detailed review.

LOL!

Thanks guy for the heads up. Who knew eh!

Ceramic is usually used to reduce friction, so that gives me an instant reservation about wet weather braking. Happy to give them a try in the wet and report back if someone sends them to me for free though.

If they've really made a scratch resistant coating, then great. Brake pad resistance is one thing, scratch resistance from grit is another, and that's exactly what you're dealing with in the wet.

Like I said, I hope they've cracked it. I always complain about how ugly I think alu rims are on modern bikes and carbon rims are still pricey.

Who knew? Anybody with some common sense.

Really good looking but give them to me for one ride in the rain and I bet I can get those rims gleaming silver.

Bought coated Vision Team 35 rims this year and that's all it took - one ride in the rain. Entire coating was gone.

Who knows, maybe this technique is better. Would be hard pressed to be the guinea pig again though.

Your trolling skills are superb, 10/10.

Your trolling skills are superb, like, um, 10 out of 10 unconstituted. Full Marks. Oh you're such a troll, buying coated rims and it rubbing off, like.. OMG

LOL

The titanuim oxidede coating on Mavics 2nd gen Open Pro's was pretty robust and doesnt wear off unless they are dinged.

mine are from 2007 and still going strong.

+breaking is better than aluminum, especillay in mountains where heat dispention is an issue.

+braking in rain is more consistant.

+wear if using swiss stops green pads is almost nonexistant - even in mountains and rain.

+in norther europwean weather - your bike wont get dirty from teh brakes when riding in the rain.

Really don't care for rims that doesn't support Disc. Ceramic coating is a joke. Who cares.