- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

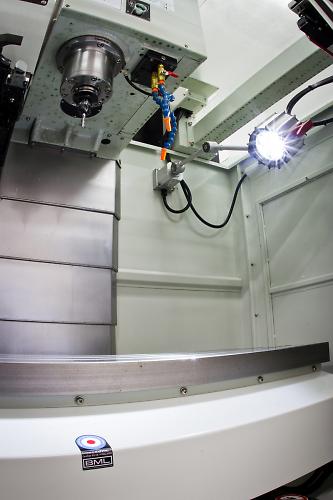

Bicycle Manufacturing Limited set up to start bicycle manufacturing in Yorkshire

Cotic founder Cy Turner has partnered with engineer Mike McDermid to launch Bicycle Manufacturing Limited, a bicycle manufacturing facility based in Penistone, Yorkshire. They aim to produce bicycle frames and parts in a range of materials, including carbon fibre, and is something they’ve spent the past two years working on.

Cy Turner needs little introduction, he has been producing mountain bikes for over ten years. The new company will initially manufacture the Cotic Rocket, a steel-framed full suspension mountain bike, which they intend to sell for the same price as the Taiwanese built frame.

Cotic of course has ventured a little into the skinny tyre world with the Roadrat. But could we see a bigger push into road cycling? We asked Cy: “Yes, we've decided to concentrate on mountain bike frames at Cotic for the foreseeable future. To be completely honest we don't have the enthusiasm for road bikes to do it justice, and without that authenticity it's hard to see a way into the market. If in the future we get someone on board who's 100% into road bikes and has the passion to carry it, we'll look at it.”

Manufacturing the Cotic Rocket is just the beginning. With the new venture set up as a separate company from Cotic, they intend to be able to offer their manufacturing services to other brands looking to manufacture in the UK. “This decision [to concentrate on mountain bike frames] was one of the main driving factors behind setting BML up as a separate entity which can manufacture for other brands. We will have a lot we can offer a road brand when we get the facilities available for other customers in the Autumn, and it makes sense to offer that to brands who are already established.”

They reckon they can be competitive on price with the Far East for producing high-end products. Instead of buying the necessary machinery and tooling off the shelf, they’ve actually produced their own equipment. They’ve built their own frame jigs because they reckon the ones available on the market weren’t suitable in terms of production capacity, speed and accuracy. They’ve developed their own automated cutting system for tubes, they’ve even made their own bespoke heat sinks and argon purge. That’s a lot of investment in the equipment.

One of the trump cards in the company’s favour is being able to reduce development time. They can turn prototypes and samples around much quicker than the long lead times of Cotic’s current Taiwanese suppliers. And it’s not just steel they’ll be working with, they say they’re able to work with all materials, including aluminium and titanium. Even carbon fibre. Which sounds jolly interesting to us.

While Cy Turner is a renowned bicycle designer, Mike McDermid brings with him a background of designing carbon composites for F1 and Le Mans racing cars. They’ll be developing a carbon fibre production facility over the next 12 months. Bicycle Manufacturing Limited says it wants to be a “one stop shop for carbon manufacturing” and can even design the layups, manage the layup schedules and make all the parts, in the same building. There’s virtually no existing carbon fibre bicycle manufacturing in the UK - Craddock recently announced they’ll be offering high-end bespoke road frames, and Moda have been developing a UK made carbon road frame, but that is yet to see the light of day.

Cy tells us “in terms of carbon tech, we can basically do anything currently available, but using methods which don't necessarily require the massive up front costs of manufacturing in Asia.”

And of course, the frames will be made in Yorkshire. “I’m extremely proud of my adopted home of Sheffield, and to have some of the Cotic frames made right here in South Yorkshire by a company I helped found makes me very happy indeed. It’s the start of a great new adventure,” says Cy.

More info at www.bicyclemanufacturing.co.uk

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- thehill 2 sec ago

worcester is horrible for riding full stop!!!!!...

- Rendel Harris 32 min 44 sec ago

BBC yet again ignoring reporting guidelines, third paragraph before we learn that the poor child (RIP) was hit by a vehicle that was conducted by...

- hawkinspeter 41 min 51 sec ago

Opposition to controversial East Bristol Liveable Neighbourhood ‘will filter away’ say council bosses...

- Rendel Harris 1 hour 26 min ago

The Milk Race sticker on the Holdsworth bag is even more anachronistic than it appears at first glance because the race was amateurs-only until...

- quiff 2 hours 33 min ago

I know it's not the same, but they are saying Quest will have free highlights.

- patto583 2 hours 36 min ago

If the rumours about 2027 are true, ASO will likely see the result of their decision to allow WB to put the tour behind a paywall. I doubt anywhere...

- quiff 2 hours 50 min ago

Just think of the weight savings you could achieve there though, because they usually have outers for the whole run!...

- chrisonabike 3 hours 55 min ago

Yeah but if you take away any chance of getting their licence back they'll turn into some kind of amoral road-bandit! * checks court records again ...

- mdavidford 4 hours 36 min ago

As far as I can see, the only place anything like that number appears in the source story is in the video, near the end, when they're chatting...

- David9694 5 hours 36 min ago

A338: Van flips over in crash on busy road https://www.bournemouthecho.co.uk/news/24981719.a338-van-flips-crash-bus... 40 mph zone

Add new comment

13 comments

has anyone had a look at the Roadrat, what a brilliant concept, a decent do anything set it up however you want frame....brilliant, I want one http://www.cotic.co.uk/product/roadrat

Oh dear, my credit card has done a runner. A Yorkshire built ti frame with Yorkshire carbon bits. Drooling at the thought.

I tried to do this in the North-East of England in the early to mid 1990s with my company Bombproof Bikes

Unfortunately we failed to produce frames domestically in the UK after failing to establish our own facility in Newcastle, and then having a string of disappointments using non-bicycle fabricators to produce our aluminium alloy frame sets

we ended up using an established frame manufacturer in Australia, who eventually disappeared with the money of about 6 companies including Bombproof, but that's another story...

It was something that we really wanted to do (manufacture domestically) and its fantastic news to read this article and see what this new company intends to do.

I can only give them my best wishes and hope their new venture will succeed, and bring domestic manufacturing (on a small volume scale) back to the UK, its long overdue!

Great news, well done chaps. I hope you get the returns you deserve for taking on a venture like this

Great news. There has been so much coverage of artisan framebuilders recently but this sounds promising for actual volume manufacture of sophisticated frames. Best of luck to them.

Brill, wish them the best of luck

What is the difference between bicycle manufacture and framebuilding?

Wish them luck, would like to know how they get on.

Good news and I hope to money/mouth one day, if you see what I mean. Those Cotic frames look lovely.

excellent, bicycle manufacture in this country is long overdue, good luck ...

Its such a good thing ! supplying the people of this country with frames that they might ad parts and turn into bikes !

I agree - good luck to them!

Good to see - I wish them every success.