- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

SRAM patent 'universal brake mount' (USPTO/SRAM)

SRAM patent 'universal brake mount' (USPTO/SRAM)SRAM patent proposes "universal brake mount" designs to eliminate disc brake rub and "improve braking performance"

A patent filed in the United States by SRAM proposes a design for disc brake-mounting that "may be considered universal brake mounts", potentially signalling the components manufacturer's next industry standard following on from the widely implemented UDH (universal derailleur hanger).

The patent, approved by the United States Patent and Trademark Office, was first reported by Pinkbike and outlines a disc brake-mounting design that SRAM suggests will result in "improved performance, improved safety, and reduced weight and cost, including frame development, testing and manufacturing cost savings", outlining its pitch for why "the example brake mounts disclosed may be considered universal brake mounts or adaptors".

Identifying the "main challenge for proper brake set-up", the patent outlines how current disc brake design can result in time-consuming, "painstaking" adjustment, "undesirable noise" such as brake squeaking, and rubbing that "generates wasteful rolling friction that slows the bicycle and causes unnecessary wear on the brake rotor and pads".

> 6 bicycle brake safety checks - stop faster with better braking

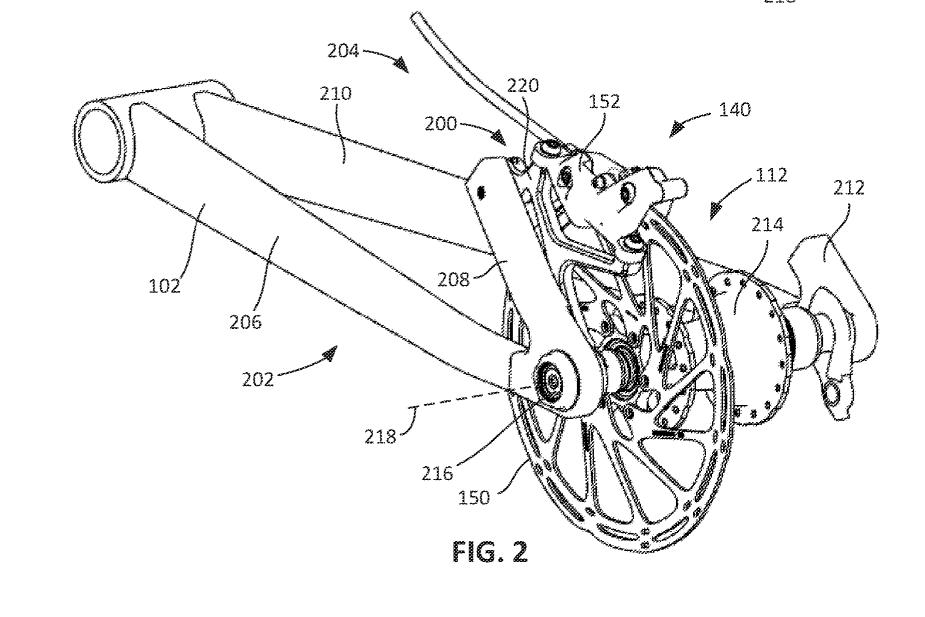

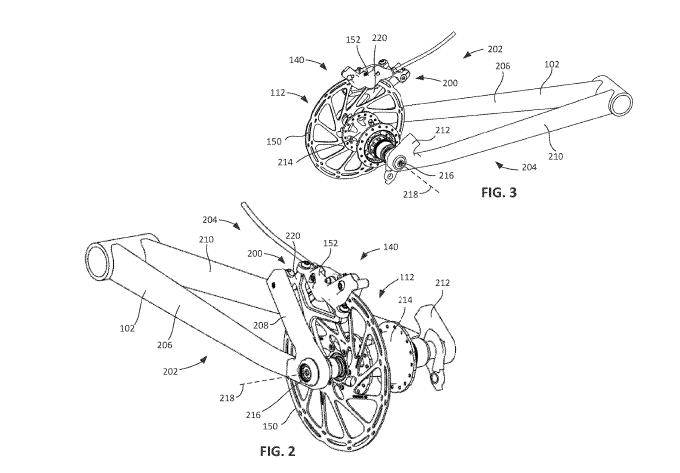

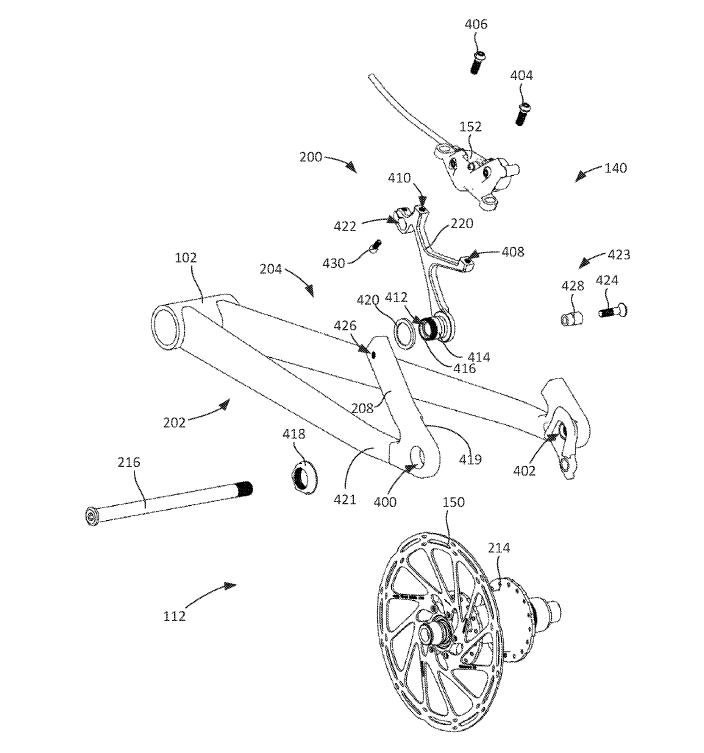

In the drawings, an example brake mount is shown and features: "A bracket having a first side and a second side opposite the first side. The bracket has bores to receive fasteners to couple the brake caliper to the bracket. The brake mount includes a sleeve extending from the first side of the bracket. An opening extends through the sleeve and the bracket. The opening is to receive an axle of a hub assembly of the bicycle. The sleeve is to extend into an axle opening in a fame of the bicycle. A distal end of the sleeve is threaded. The brake mount also includes a nut to be threadably coupled to the distal end of the sleeve when the sleeve is inserted into the axle opening in the frame."

Talking about the potential benefits of such a design, the patent suggests the example brake mounts disclosed "may be considered universal brake mounts" that can be used to mount "various brake calipers".

Getting very technical, by "creating a stronger or absolute axial and radial reference to the hub assembly rather than the frame", the patent states that "even if the dimensional tolerances of the frame allow misalignment between the rear hub assembly and the frame, the brake caliper and the brake rotor remain axially and radially aligned".

> Your complete guide to SRAM road bike groupsets

In short, SRAM reckons this will mean less time setting up and aligning your brakes. On top of that the patent cites a reduced or completely eliminated chance of unbalanced braking forces and unnecessary brake rub, thereby "improving braking performance and prolonging the life cycle of the brake components".

"The examples disclosed are also advantageous for vibration management," the patent continues. "Resonance frequencies can cause squealing and other performance and safety issues."

Ultimately, it concludes, the designs would "allow frame independent brake system optimisation that results in improved performance, improved safety, and reduced weight and cost, including frame development, testing and manufacturing cost savings".

Dan is the road.cc news editor and joined in 2020 having previously written about nearly every other sport under the sun for the Express, and the weird and wonderful world of non-league football for The Non-League Paper. Dan has been at road.cc for four years and mainly writes news and tech articles as well as the occasional feature. He has hopefully kept you entertained on the live blog too.

Never fast enough to take things on the bike too seriously, when he's not working you'll find him exploring the south of England by two wheels at a leisurely weekend pace, or enjoying his favourite Scottish roads when visiting family. Sometimes he'll even load up the bags and ride up the whole way, he's a bit strange like that.

Latest Comments

- Rendel Harris 21 min 20 sec ago

Thank you for putting "opposed" in quotations; quite clearly Attenborough received a doubtless extremely biased and disingenuous letter from a...

- John G 27 min 2 sec ago

“A common mistake that people make when trying to design something completely foolproof is to underestimate the ingenuity of complete fools.” ...

- maviczap 34 min 3 sec ago

I was the same, there's a Facebook group for Wheeltop owners, lots have good experiences, but also plenty with issues, so I'm holding off until...

- chrisonabike 39 min 52 sec ago

That's because of old-fashioned thinking and a conspiracy of the Legacy Bike Manufacturers!...

- chrisonabike 1 hour 15 min ago

Ah, but is it just "for the lolz", "because free speech", "the real danger is the wokery / left / those pushing social experiments on everyone*"?...

- mdavidford 2 hours 51 min ago

I would assume there's some kind of transmission in this bit. Don't know about a 'clunk' though - if it's capable of mimicking all kinds of gear...

- HollisJ 3 hours 24 min ago

Weird. I went there a few weeks ago and all I saw was a cycle lane and plenty of free parking provision next to it, no keeerrraazy wiggly lines....

- chrisonabike 5 hours 1 min ago

I suspect a different poster - our consistently unlucky (yet somehow surviving) wheelchair user never had anything good to say about cyclists!

- Rendel Harris 5 hours 38 min ago

That's a very good point, I remember once speaking to somebody who had volunteered in Gaza as a medic who said that the vast majority of the...

- OldRidgeback 6 hours 9 min ago

It isn't the first time BC has avoided sending riders to events, even when there have been riders with potential.

Add new comment

16 comments

Woohoo Sram, let's continue to make wheel removal and placement slower! Anyone working as a bike mechanic will know that this will not eliminate brake disc rub. Just like UDH is in no way an improvement to anything else than reducing the amount of derailleur hangers - things are and will be crooked in bikes no matter how much industrial designers and engineers draw with CAD.

I build carbon frames in my shop for my own use. The UDH is brilliant. This DB mount would eliminate the 2 axis milling i have to do on the dropout. It probably just needs a 20mm diameter hole and a bolted on stud on the seat stay, so Theres only one axis milling. The stud attachment is " sliding" so it needs to be aligned with the axel, but should be fairly easy. My dropouts could be much less volume too. Also on small frames the caliper has to fit under the seatstay and this can be really tight with dropped seatstays, so it frees up the seatstay angle too.

What is the load path here - where do the forces go?

It seems like the bracket is clamped to the frame by nut 418 maybe? I would have thought the torque generated by braking 50kg+ (assuming the other (greater) half goes to the front) is pretty substantial - I wonder what torque that nut is meant to be done up to.

Also, the bracket is in a parallel plane to the disk itself. As such, when braking, there is a rotation force around the radial axis. This already happens - the frame must resist this. But in this design, what is resisting this twist? Is this the sleave and coupling to the seat-stay?

It looks like the braking forces are transmitted through a pin or bolt (item 430) between points 422 and 426 on the exploded view diagram - very much like a conventional disc mount in terms of loads applied to the frame. No need for the big nut to do anything more than stop the brake falling off when you take the through axle out.

The whole setup looks quite sensible to me. No idea if it will catch on of course.

I'm sure they have checked everything better than I could ever do, but this axle opening 426 in the frame might add more torsion and shear than compression (as it does on the traditional system). And only half of the (seat) stay width is taking all these forces (at least on this picture).

Which doesn't sound great for carbon frames? in this figure it's fixed on a seat stay, these are usually much lighter than chainstays. Of course they could be designed differently.

If the bolt 424 or 430 allow to laterally ajust the caliper to the rotor (a very small amount of course else the longitudinal alignment would suffer), that would be better than the actual system where the 2 main bolts need to be loosened, then tightened after trial and error.

That said the main cause of squeaks is usually bent rotors, which is of course not addressed by that system. When I replace a set of wheel, the rotors usually come into place after a few kilometers, so although they might squeak in the beginning, I don't need shims or adjustments but only some patience...

I dont see how is this is much of a step forward. Unlike the UDH where there is one fixing point - so its 100% relative to the Thru Axel - on this set up there is a 2nd mounting point to the frame a couple of cm up the seat stay.

Once you have 2 mounting points you lose the benefit of a single spacial relationship between the caliper mount and the wheel/rotor assembly.

Plus its fairly ugly and re-introduces the problem flat mount got rid of which is a tight flush (aero!) fit of the caliper with the frame.

I think it will help - the second fixing point is a sleeve, and the bracket then clamps to it. This means the bracket can still define itself axially, even if the chain stay is not in the perfect position.

Agreed it is not as pretty as engineering the chainstay, but maybe it is very difficult (=more expensive) to get the proper tolerance on a chainstay which is designed to flex.

I've had to pos-ream the brake tabs of my last two bikes so I'm all for this solution! The UDH was a killer move from Sram, curious to see where this one goes

So it is only universal to the frames that are designed to work with it?

Well I guess in some ways it could be unisversal to bikes that don't have disc brake mounts. But none of my rim brake frames have through axles, so it won't work as a retrofit option for them.

I can see it has some potential benefits, but counter to the the iead you spend less time setting up your brakes, looking at this your brake caliper comes off every time you remove your wheel to clean the bike, fix a flat etc. which sounds inconvenient to say the least.

There's no way to retrofit this without milling, drilling and reinforcing a frame...

Calipers wouldn't come off when removing the wheel - you'd just remove the through-axle and then the wheel.

If your old bike is made of steel you can convert to disk, just find an experienced metalworker, give him a mocked up example and ask him to make it in metal for the rear and buy a new disk fork for the front. See attached picture of my vintage tandem lockdown project. The end result works brilliantly!

Thats a lovely job. Kudos to the welder, especially if they aren't a frame builder

Worth noting that a good frame builder will have a jig for welding on disc brake tabs.

The guy restores classic cars and seems to know his stuff. He also welded on a derailleur hanger made out of a bolt on one and it must be well aligned because the gear change is perfect, even with the extra long cables! I needed this to have the wheel at the rear of the dropout so that braking forces didn't move it, the device you can see attached to the quick release is called a hurdy gurdy and resists the chain tension.

and a picture of the full bike, it has since been upgraded with drop bars at the back.

Hea Boost Plus- come in your time is up.