- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

University of Maryland (1).jpg

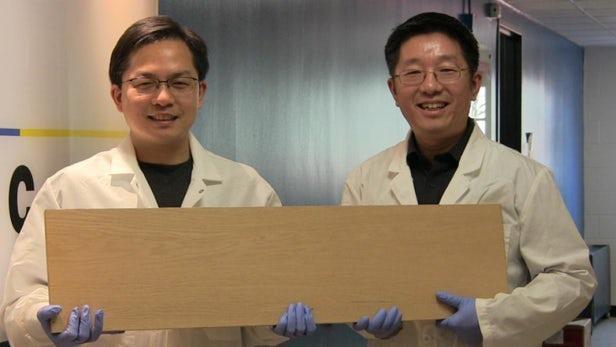

University of Maryland (1).jpgCould the bikes of the future could be made from “super wood"?

Researchers at the University of Maryland in the USA have developed a simple strategy to transform natural wood into a high-performance structural material with a more than tenfold increase in strength and toughness. The researchers, reporting their process today in Nature journal, say that this treatment also results in a material with greater dimensional stability that could be substituted into any application where steel is currently used, such as cars, aeroplanes, buildings and, presumably, bicycle manufacture.

We’ve reported on wooden bicycles many times in the past, but what’s different here is that the University of Maryland researchers, led by Liangbing Hu, are proposing that bulk natural wood is transformed using a two-step process that involves the partial removal of lignin and hemicellulose through boiling in an aqueous mixture of sodium hydroxide and sodium sulphite. The material is then mechanically hot-pressed at 100°C, leading to a reduction in thickness of about 80%.

According to the researchers, “[This leads] to the total collapse of cell walls and the complete densification of the natural wood with highly aligned cellulose nanofibres.”

This treatment is said to work equally effectively for various species of wood – both hard woods and cheap and fast growing soft woods – and results in a material that has a specific tensile strength that's higher than that of high-specific-strength steel (HSSS), and even of lightweight titanium alloy (Ti 6Al/4V).

Check out 10 stunning wooden bikes here.

"This could be a competitor to steel or even titanium alloys, it is so strong and durable," said Liangbing Hu. "It's also comparable to carbon fibre, but much less expensive."

“The large increase in tensile strength of the densified wood is not accompanied by a decrease in toughness,” say the researchers. “Both the work of fracture and the elastic stiffness of the densified wood are more than ten times higher than those of natural wood.”

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- Backladder 2 hours 5 min ago

The solution is simplicity itself, you drive in forwards and then once on your own land you turn the car around by whatever means necessary so that...

- chrisonabike 2 hours 37 min ago

Haven't spent much time in Bristol for decades - but back in the day much was pretty gridlocked at least once per day. Has it got better?

- Secret_squirrel 3 hours 1 min ago

Um. Call me picky but what's the point in spec'ing an internally routed head tube then not using it? it looks a bit naff.

- David9694 3 hours 50 min ago

Another Conservative bemused at how but a Conservative policy is turning out

- Global Nomad 9 hours 20 min ago

would be good to see you test the Newmen wheels the weight/price ratio is extremely good and suggests that europeans can match the chinese in this...

- mdavidford 11 hours 39 min ago

I don't think you have. I think their point was:...

- jamesha100 21 hours 34 min ago

Should be a lifetime driving ban. Who could seriously argue against the justice of that in this case?

- thax1 1 day 4 hours ago

Another 'sound-alike' mid tier offer, so I get all excited and buy a bunch of them thinking I've got an absolute steal. Only to then realise I've...

- mdavidford 1 day 4 hours ago

first cast out the beam out of thine own eye

Add new comment

20 comments

"Improved Wood" has a long history.

As usual, most modern innovations result from decades of reinvention. I first read about it in a British 1930s magazine called "Wood". Then it was describing wood impregnated with phenolic resin, heated and compressed. I recall that one use was to make durable telegraph pole insulators. In my house I have a different kind of improved wood: Accoya, which is an acetylated timber, where the wood has been rendered waterproof and therefore rot proof and dimensionally stable. It isn't compressed or void-filled so it's strength is probably not much different to the softwood that it's made from. The abstract above doesn't mention it, but this new process would, presumably, introduce a waterproofing resin as well. This doesn't have to be another environmental disaster. Sustainable forestry is already viable and subsequent manufacture should be energy efficient.

I get loads of junk mail about it. Must be my age.

Or my saddle.

So now we have to worry about termites.

I'm wondering what the mass of it would be like, if they're increasing the density that dramatically would it not become quite heavy? or has the prior process already reduced the mass? If it's light enough as a solid product then I could see this being a pretty cool product for hybrid type bikes, a good waterproofing sealant and it'd be great.

More interested in industrial processes for this, or the suggested use in cars etc, Morgan might be very interested.

The density may increase, but because of the tenfold + increase in strength you need one tenth the mass. Bamboo bikes are slightly heavier than a steel bike. I'd say a wood fibre frame could readily come in at a similar weight to a CF frame.

As far as 'you can't deform wood', steam- bent timber and ply has been around for probably about as long as either material has been in use in furniture making, at least.

In some respects this sounds a little like 'thermowood' - treated under heat to make it far more rot-resistant than the original timber.

Can the 'hot-pressing' be used to form the material into shapes? Like is already done with carbon fibre frames? I have only read the abstract so I may be putting 2 and 2 together and making 5.....

There seems to be a REALLY big issue here, in my mind at least.

Regardless of how much stronger it is than carbon fibre or Ti or Steel - how would it be made into a bike frame?

You can't extrude a tube from wood, it won't deform plastically to allow you to bend a sheet into the shape of a tube (like some MTB tubing) and you can't mill wood hollow (not without seriously compromising the structural integrity).

Sure you could mill/turn solid bike tubes from wood and glue them together, but that's just going to be pointlessly heavy.

The great thing about carbon fibre is you can lay it up into pretty much any shape you want yet it still be light and stiff - moreover, you can't control the mechanical properties by laying up the carbon fibre differently.

You don't have control of the grain of wood unlike you do carbon and you can't make it hollow - so it won't replace carbon.

It may be stronger than Alu, Steel and Ti but you can't easily extrude it, unlike the metals - so I don't see why it would replace them.

Chobham Armour is extremely strong and has it's place in engineering applications, but bicycles isn't one of them. I think it is the same for super-dense wood, (I imagine it could be a fantastic way of producing large strong girders for buildings though).

Not having read the study, it sounds like this is basically modified wood fibres in a sheet form (like single layers of plywood) and so can be treated in much the same way as carbon fibre. In reality, wood fibres are simply hollow carbon fibres, ply wood layers are .8 - 1.2mm thick, so these sheets (losing 80% of thickness) would be .15 - .25mm thick. Form them in sheets into tubes, the same as carbon fibre / kevlar / fibreglass, and resin them together.

Ah, I see!

That starts to sound more interesting.

Surely the greatest benefit is that it can be worked with hand tools? Saws, chisels, planes, and you can glue it together with pva glue. Who will be the first to produce a mortice and tenon-jointed frame?

I wouldn't be using PVA glue it's water soluble, Gorilla glue or No more nails would be a better option

Ccement is water soluble too. There are really good exterior (water proof) pva's in standard use in the construction industry. For a whole host of reasons gorilla glue (very brittle) and no more nails (not a true glue) would be unsuitable, but probably an epoxy glue (as the fibres will almost certainly be resined) will be the go.

Some bikes give me super wood.

I would have thought the coating on the dried/compressed wood maintains weatherproof ability but the ingress of water on that type of material unless submerged shouldn't ordinarily be affected short to medium term at least but certain atmospheric conditions and being exposed to that continuously might have a greater effect and faster.

Crash resistance and having same/similar abilities to CF would be the major comparator if it's to become a big thing and not a niche product like bamboo. Steel, ti and alu are already a well known quantity, it's going to take a lot of swaying and investment plus a huge glob of faith based on saving money to make a big player change tack and go with this. With no known history I can't see anything but a couple of offerings in the bike industry even in 10 years but who knows.

The only other concerns are where is the wood coming from, how much waste is there, are the by products usable for something else and what kind of pollution does the caustic soda/lye and Sodium nitrate produce, the latter a bi-product from sulfurous acid IIRC

It's just never going to happen. I just can't see anyone having faith in wood or getting excited about it.

The construction industry might be interested though.

Very interesting.

No comment on how hard/easy the material is to work with compared to various metals and I'd be interested to know about short and long term effects of exposure to water.

Possible limiting factor for some applications would be the length of the product.

Might be a good incentive to start planting more trees than are being felled...

Wonderful news. If only there were still some rainforests that require denuding.

They talk about it more in the Nature podcast this week https://media.nature.com/original/nature-assets/multimedia/podcast/nature/v554/n7691/nature-2018-02-08.mp3 . It sounds like an interesting, possibility more sustainable tech. As with all wood at the moment moisture is its Achilles’ heel.