- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

9 things they don’t tell you about tubeless tyres

You’ve probably heard lots of good things said about tubeless tyres – better puncture protection, comfort, rolling resistance and so on – but have you heard about the downsides? The tyres can be a pain to fit, sealant makes a mess everywhere and there are huge compatibility issues, as we explain below.

- Buyer's guide to tubeless tyres — all your options in new technology rubber

Tubeless might just be the best thing since the invention of the pneumatic tyre, or it might be a complete waste of time. The history of bicycle product development is littered with as many rubbish products as significant ones, but in our view tubeless tyres are a big step forward (you may beg to differ). Even so, as the technology stands today tubeless has its drawbacks – some of them are pretty well known, others less so.

Here are some of the cons of current tubeless tyre technology.

No more punctures...

Before we get into the downsides, let’s start with a positive. One of the key benefits of a tubeless tyre setup is a greatly reduced risk of puncturing. The liquid sealant inside is able to seal smaller holes caused by glass, flint or stones and plug the hole because it dries very quickly.

When you witness it happening firsthand and are able to continue riding without needing to replace the inner tube you'll be convinced that this is the future.

...but doesn’t plug all holes

That said, tubeless isn’t invincible and the sealant won’t seal all holes above a certain size, generally about 6mm, because it’s simply overwhelmed by the speed of the air rushing out. This means you might, in rare cases, find yourself with a flat tyre and sealant everywhere. Messy!

For really big holes that the sealant can’t fix, you have two choices, either whack a tube in or use a tubeless repair kit involving an odd rubber anchovy – yep, that's what they're called – which you stuff into the hole to seal the tyre. They’re popular with mountain bikers but yet to be embraced by roadies. You can read a review here. So that's something else you need to buy. The price is creeping up.

You still need to carry a spare tube

Yup, it’s advisable to carry a spare inner tube even though you’ve banished them from your wheels, just in the rare event that the sealant can’t plug a hole.

Installation issues - the tyre just won't fit

This is the biggest problem with current tubeless tyres. Fitting a regular (non-tubless) clincher tyre and inner tube is mostly painless. At worst you might need a few tyre levers, but after that, a small pump will get the tyre inflated onto the rim. It takes about five minutes.

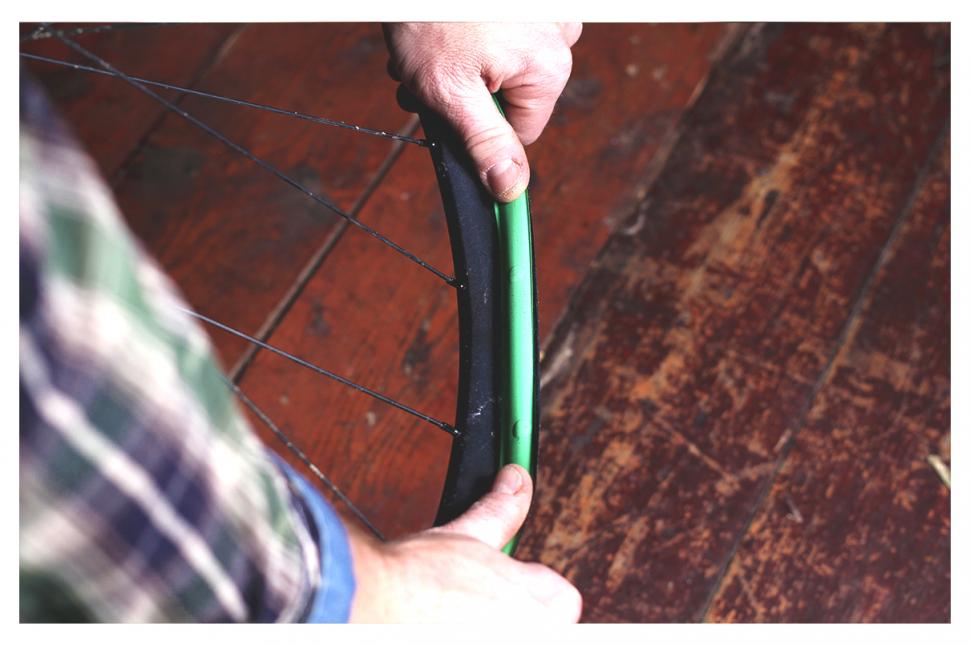

Some tubeless tyres, however, can take much more time to get fitted to the rims and involve much cursing. The problem is due to there being no one standard that all rim and tyre manufacturers adhere to. Also, because you need a very good seal with the tyre bead on the rim, it generally involves a very tight fit... in some cases so tight that you need multiple tyre levers. We've known people to give up, it can be that difficult.

When you've got the tyre onto the rim, it's not all over. Nope, in some cases, you need a tubeless-specific pump, CO2 canister or compressor to deliver the big burst of air needed to pop the tyre up onto the beads.

Much of the problem with tricky tubeless installation comes down to the issue of compatibility between different brand rim and tyres, and a lack of a universal standard. There is wide variation in rim and tyre size and bead stiffness, which affects installation and safety. Keeping the tolerances small is crucial to the success of the system because without an inner tube pushing the bead against the inside of the rim there needs to be a really good fit to ensure the tyre doesn’t come off the rim.

- One step closer to a road tubeless standard? And why this matters to you

The result is that some tyres are a breeze to fit to some rims, with the complete opposite true of a different tyre and rim combination.

This is slowly changing, though, with more brands making their tubeless tyres to ETRTO standards and we have to say that similar issues can affect tubed clinchers. That said, the issue seems to be magnified with tubeless.

There’s a difference between tubeless-ready and tubeless rims

You do need to be a little careful if you’re upgrading to a new wheelset when going tubeless as there is a difference between a tubeless-ready rim and one that is designed for tubeless-only tyres.

The difference can be found at the rim bed and specifically, where the tyre bead sits. Hookless rims (above) are designed for tubeless tyres (although you can still use them with an inner tube up to certain pressures; different brands offer different advice on this), and as the name suggests, they do not feature a hook on the rim.

Tubeless-ready rims, meanwhile, offer you a wider selection of tyres as you can use standard clincher tyres and tubeless-ready tyres. A tubeless-ready rim (above) keeps the hooks that you’d expect to find and they don’t come with the lower max tyre pressures of hookless rims either.

Which one is better? That’s not a debate that we’ll get into today.

It can be messy

All that sealant invites the risk of a mess, and sometimes tubeless can be a messy thing. If you get a puncture while riding, unless you have mudguards you could spray sealant all over your frame, bum and back and anyone riding behind you. I’ve seen this happen and while it’s funny, it’s not nice at all.

When a tubeless installation goes wrong, you can be left with puddles of sealant on the floor or ground of your workshop/kitchen/office. Try explaining why there’s white gunk everywhere to your other half!

Tubeless can be heavier

The extra material needed to make a tubeless tyre, and in some cases, the rim as well with additional rim strips, plus the tubeless valves and necessary sealant, means that even though you’re ditching the inner tube, a tubeless setup can be heavier.

The tyres are generally heavier too. A Continental GP 5000 TL 28mm tyre weighs 340g versus 250g for a regular GP 5000 tyre. Removing the inner tube, however, does save you in the region of 100g but you're adding back 50-60g of sealant which negates some of the weight saved, and those tubeless valves are probably a little heavier too, and there's the rim strip if your wheels need it.

Just don't go expecting tubeless to shed loads of weight from your bike with tubeless, although in some cases it can save a small amount. Plus, if you're carrying two spare tubes just in case, that's your weight saved added back to the bike.

- Buyer's guide to tubeless tyres — all your options in new technology rubber

It can be an expensive upgrade

Wheel manufacturers have been quick to embrace tubeless and a lot of new road and gravel bikes are now being sold with wheels that are tubeless-ready, so you’re halfway there.

If you want to go tubeless, you’re going to have to buy new tyres. Now, unless you need to replace worn-out tyres, then it does mean removing a perfectly good set of tyres and replacing them with new tubeless tyres.

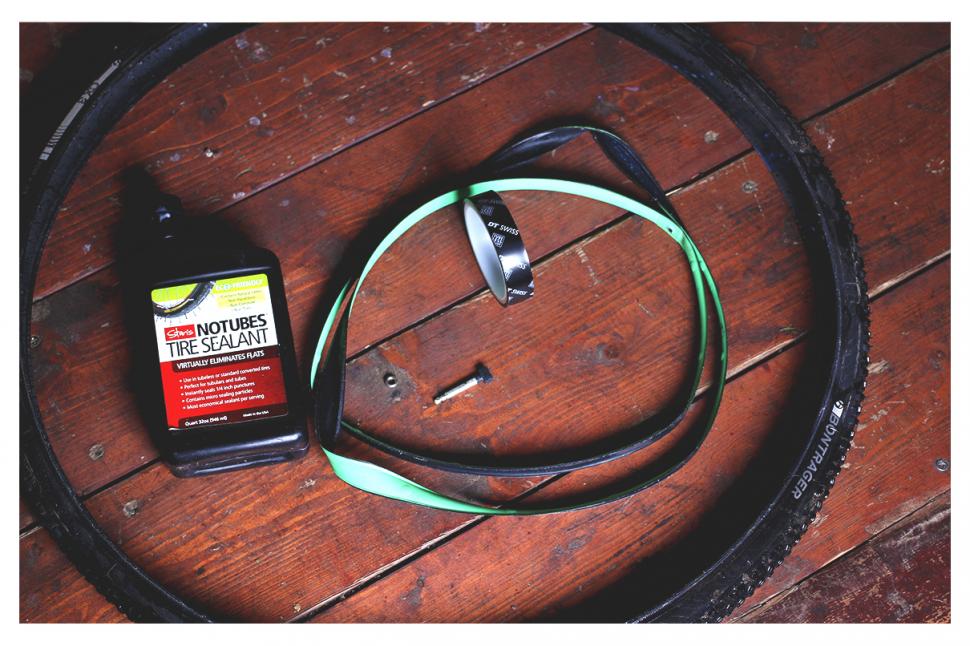

Tubeless tyres are a little bit more expensive than the clincher model and you’ll also need to get yourself tubeless valves, sealant and rim strips if the rim bed isn’t sealed.

If your bike doesn’t currently have tubeless-ready wheels then you’re going to need to buy a new set of hoops too.

One alternative to buying new wheels if yours aren't tubeless-ready (and we're not recommending this) is to go ghetto. In the early days of tubeless, especially in the mountain biking world, it was common to use regular non-tubeless tyres and rims and use rim strips and sealant to achieve a tubeless setup. With the higher pressures involved in a road bike tyre it's probably safer to follow manufacturer guidelines and only use approved tubeless components.

Sealant eventually dries out and needs topping up/replacing

Sealant is the magic ingredient that gives tubeless setups their big advantages over inner tubes, in being able to seal punctures.

The liquid sealant required of a tubeless setup doesn’t stay liquid forever. It’ll eventually dry out. I’ve had many alarming cases with road and mountain bikes when I’ve whipped the tyre off only to find the sealant completely dried out!

Muc-Off claims its sealant lasts up to six months after which you’re going to need to top it up. In most cases, the sealant is going to dry out long before your tyre wears out. Now you can either carry out checks every few months by popping the tyre off the rim, or the easiest option is to just top up the sealant every few months.

It isn’t easy to add sealant

When you do need to add sealant, there isn’t really a foolproof way to do it.

Yes, you can remove the core of most tubeless valves, but over time they love to get themselves gunked up with old sealant – and that can make removing the core a nightmare. Then, once you manage to get it out, most sealant bottles don’t fit the valve properly so you’ll inevitably get some sealant dripping down onto the rim, tyre sidewall and – in the worst cases – down onto the carpet. Our Liam is terrible for this.

Now there are specific syringes available for this job but even those are prone to throwing sealant everywhere. This all means that you probably want to have a rag ready.

Sounds like tubeless is a terrible idea then?

If all that has put you off the idea of trying tubeless, we should end by saying that in our opinion the pros of tubeless tyres outweigh the cons. Getting the tyres on and off can be messy and a general pain but the beauty of tubeless is that it's not something you have to do often. There is hope for tubeless to become much more accessible and easier with the industry finally agreeing on new standard guidelines to maybe all these troubles will be a thing of the past and nothing more than teething problems.

Do you love or hate tubeless? Let's hear your thoughts in the comments section.

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- Secret_squirrel 4 hours 51 min ago

Um...no. Spitting is grim and there is never any excuse.

- Another_MAMIL 7 hours 47 min ago

Q36.5 Gregarius Essential Bib Knickers fit the bill: 3/4 length bib tights for warm weather.

- Rendel Harris 7 hours 58 min ago

Jolly good. Only it hasn't been and it is still a public bridleway. Feel free to look it up.

- jaymack 8 hours 48 min ago

"...it feels more like a £100+ jersey". It's almost as if cycling apparel is over priced.

- mike the bike 10 hours 39 sec ago

I've had a few Lezyne bits and bobs over the years and while it's true I've never bothered to return anything under warranty, I've had a couple of...

- mark1a 9 hours 3 min ago

There's a transition period. For the benefit in kind (BIK) tax to the employee, it will be treated as a goods vehicle as it is now (rather than a...

- hawkinspeter 10 hours 12 min ago

Parents say East Bristol Liveable Neighbourhood makes roads '100 times safer' for children:...

- mdavidford 10 hours 18 min ago

Isn't basically all carbon recycled? From stars?

- velodinho 11 hours 34 min ago

As witnessed at so many infrastructure improvement projects similar to this one, all those who object should ignore the consultation and pray at...

- Nagai74 13 hours 22 min ago

It's a DLO to those in the trade.

Add new comment

126 comments

Be careful in the wet as I found them very slippery when run at >70PSI. I use GP5000TLs these days and haven't got a bad word to say about them which is surprising as others seem to find them very difficult to mount to rims which has not been my experience.

Ouch!

That particular bike doesn't go out in the wet much, now it has carbon wheels (rim brake) I think I'll be even less inclined to risk it!

Am going to try GP5000s or Hutchinson Fusion 5s next. Have heard good things about both.

If tubes are so great why are they not used on cars or motorbikes? Given the length of time it takes to roll new innovations out (where you either get a new bike with them on or consciously choose to adopt them early) is it surprising that they are the preferred choice? It just takes time. In the meantime, continue with tyres and tubes if it suits, it really doesn't matter to anyone else if that's your bag.

Just take the tyre off and put a conventional tube patch over the hole on the inside of the tyre on the conventional way. Done it a dozen or so times with no problems.

'You can run lower pressure and get more comfort and grip with little to no increase in rolling resistance'. Really?

I have invented an electricity generator that produces more power than it consumes - honest!!!!

Aerospace connected professional? That's a very impressive way of saying nothing at all.

Maybe because tubeless works on cars and motorbikes? Bicycles, however, seem to need sealant to make it work. If sealant was so good...

Actually, this claim can be accurate, as you don't need to overcome the hysteresis of an inner tube.

It's still a hell of a lit easier just to swap an inner tube once in a while than to arse about with tyres that don't fit and hortible sticky goo, though...

"Tubeless" bicycle tyres don't need sealant, "Tubeless Ready" tyres - which are the majority - do. Tubeless Ready trades off compliance with the need for sealant to maintain air integrity. Sealant is also used in car, motobike and other 'tubeless' implementations - most usually post-puncture though, e.g. an increasing number of car spare tyres are being replaced with 12V pumps with inline sealant canisters.

To me it’s all about personal experience.

Some claim that their tubeless tyres were easy to fit, simple to inflate and seat the beads on and they haven’t suffered a puncture since.

Others experience is the polar opposite.

And that’s the problem. In theory they are everything you would want - easy to install, simple maintenance which can be carried out at home in a warm garage rather than by the side of the road in the cold and rain. They’re lighter (hmmn), can be run at lower pressure, provide a more comfortable ride and above all else will pretty much do away with the scourge of all cyclists - punctures.

Except they don’t. The reality can be very hit and miss. Yes, sure you’ll find converts who swear by them who’ve never had an issue, but when they do, which they inevitably will some day, then the benefits can be outweighed by the downside.

An example. I have three or four mates who just keep banging on about how brilliant tubeless are. And I’m sure they really do think they are. But, in the last few months I’ve been riding with 3 of them who have suffered punctures that won’t seal. Last one was on Tuesday. It took nigh on 20 mins before we were riding again. Why? Because of the 3 people on tubeless all making suggestions as to what he should do. I’ve read up extensively on the subject and had a pretty good idea of what he needed to do. He is old school and thought ‘just putting a tube in there’ was the solution.

So he starts to remove his back wheel and then others chirp up about will you be able to get the tyre off? And back on? Have you got strong enough tyre levers? You know you’ve got to take the valve out right? Have you got the tool to do that? And so it goes on.

Eventually they decided to find the hole and sure enough it was about a 2-3mm split/ hole/ damage. The sealant couldn’t seal it because 1. The hole was too big and 2. At road pressures the vast majority of the sealant was now deposited on the road in a stream and all over the rear of his bike (winter bike with full guards), including all over his brake disc rotor.

Being told of the pitfalls of removing the tyre and the valve etc etc he started to feel a lot less confident and was getting his phone put to call for his wife. I merely stated that he just needed a worm and some sealant and a method to pump it back up. Trouble is, he didn’t carry worms or the kit required to install one, or any sealant.

Lucky, one of the other riders did, so they then proceeded to fit a worm (neither of them having done it before and unsure of the correct technique). One had to be warned about poking the sharp tool straight into the tyre and possibly damaging the rim tape, so he then proceeded to push it through at a shallow angle. Success.

Now he needed some fluid as mentioned before most of his was now not in the tyre. Luckily, mate no2 was well prepared and carrying the right kit including a small bottle of sealant. I had to laugh as he had one of those fake bottle storage tool kits which was FULL of kit for fixing tubeless punctures and a spare tube! Yep, MUCH lighter than a simple lightweight tube and a tyre patch! Not.

so they get the sealant in and then he finds he can’t get it to inflate with his minipump, so mate no5 (old school, full size frame pump!) comes to the rescue and the tyre is inflated. We are off again.

So, that was 20mins of faffing, agreed that some of that was down to incompetence, but his ‘plan A’ was simply to bang a tube in there. I suspect we would have stood there even longer as he broke successive tyre levers removing the tyre (he said it was a pig to fit originally). And no doubt with cold, wet hands and increasing frustration levels, egged on by the relentless piss taking by the onlookers (de rigour non?) would more than likely have pinched the replacement tube trying to get the last bit of the bead over the rim.

This is one anecdote from the three I have had the (dis)pleasure to witness first hand. All were similar in that the supposed benefits failed when the sealant failed to seal. One of the other two did require a phone call and a very long drive for a very angry missus.

The argument that tubeless had prevented ‘lord knows how many’ punctures that they didn’t even know about may well be true, but unless they inspect their tyres for the thorns etc that are still in them they will never know! I’ve had two punctures running tubes tyres in the last two years. Both fixed roadside (one in the freezing cold and wet) in approx 5 mins. No tyre levers required, simply put the tyre in the well and ‘work’ the opposite side over the rim. Remove the cause, tyre boot if you have too (I haven’t EVER used mine yet), put in new tube, bang in a CO2 cartridge and jobs a good ‘un.

The problem I have is that there is no standard yet so rim and tyre combos are hit and miss. There are too many variables from tyres that are so tight you can even get them on the rim at home, rims which don’t need tape to ones that need more than one layer. Tyres and rim combos that once you have them on the rim you can pump up with a mini pump to others that just won’t seat after two hours with a track pump, a shock pump, a 2ltr coke bottle pump(!) to an airline with compressor.

And then you’ve got sealant, most of which will not seal at road pressures (so it drops significantly before it actually seals) and then if you pump it back up it can blow the plug out (happened with one of my other mates when he tried to top up his tubeless at the cafe stop after it had eventually sealed roadside), which dries out over time so needs to be checked, topped up regularly and makes a bloody mess of everything as it sprays out. And going back to my anecdote, do you think his disc brake pads are now ruined due to the contamination by latex sealant? I donno...

So, to summarise when they work they may well be great. When they don’t, they may well still be great, but when they don’t, they may end up being terminal roadside. The same can’t be said for clinchers with tubes. There are tight tyres and loose tyres but you can pretty much 100% of the time get a new tube in, seat the tyre and inflate it to carry on with your ride. That’s why I haven’t been convinced to change yet.

PP

Some good points in the article, mostly that tubeless is difficult and pointless for bicycles. It adds weight and the "sealant" dries out every couple of months. Why complicate something unnecessarily? Is it the Emperor's new clothes? Again?

It not a faff if you know what you are doing.

Regarding weight, they probably weigh less than having an inner tube.

My take.

Tubeless with discs? Yes. The low pressure/bigger contact patch complements the extra power of hydraulics perfectly.

Tubeless with rim brakes? No. The extra faff isn't worth it & the rim brakes won't be able to take advantage of the extra grip.

Disclaimer. I live in the Dales. Braking power is highly desirable, especially in the (regular) wet.

Also not mentioned. Need to replace a worn tyre? New sealant required too £.

Finish Line Kevlar sealant does seem to last as long as the tyre.

IMO

The rolling resistance thing isn't necessarily true, clincher GP5000s with latex tubes have lower rolling resistance than tubeless GP5000s.

Might go tubeless on the winter bike/commuter, but for the nice bikes latex tubes are simpler and cleaner. No punctures to date on summer roads or winter CX courses!

Never been tempted by tubeless. If you buy good quality tyres and keep them pumped up hard you wont get many punctures if any. I use Michelin Pro 4 Endurance and never had a puncture.

The Pro4 Endurance is indeed a tyre that breaks all the rules. It somehow combines lightness with toughness and manages to be both long-lasting and grippy. I've just jettisoned my second consecutive pair, only because they were worn down to nothing after about 6000 miles of all-season work.

Unfortunately the Pro4 is now obsolete and its successor the Michelin Power lacks the all-round puncture protection layer so it isn't for me. I'm also wary of buying years-old Pro4s from stock; I've found in the past that unused tyres don't last for ever and begin to craze and crack after a while.

Instead, I've just bought Pirelli's new Cinturato, it gets a brilliant write-up on bicyclerollingresistance.com and I'm hoping they will repay their frightening £80 cost.

Indeed - if you're not that fussed about ride quality, wood's very good like that too. Also sustainable.

Hasn't road.cc told us what they don't tell us about tubeless quite a few times now?

Article needs a thorough update before they run it again in a month. Some pro teams are using tubeless this year, I think there have been a few wins on it. There's loads of tyre choice now. As for the rest of the scare stuff, traditionalists are never going to like tubeless. Or wide tyres. Or disc brakes. And so on.

Hello, is that you Boatsie?

I've tried them, I found them to be about as useful as tits on a fish, the original 2 sets I had, are all in the bin now, I got about a couple of hundred miles out of them, never again.

What were you doing with 'them' ? Indeed, what are 'them' ?

Just gone tubeless on my N+1 killer/DIA bike. £300 so not cheap but I needed new wheels anyway as I wanted to go down to 650B on that bike. Most of the riding I do on it is on sandy gravel tracks in and around the New Forest so it really needed fatter, lower pressure rubber.

Apart from doing a fantastic Mike Stead-inspired Pollocking of the shed with 4oz of Orange Seal it's gone very well. Top tip with the Milkit system - read the instructions and don't think "Oh I've taken the valve core out so the tyre must be flat, right?"

I'm running WTB Senderos which are about as chunky as you can get on a road bike running mudguards. Deal with deep mud and sand just fine. Can't really fault them. Set up really easy on a set of FSA Afterburner wheels which looked fantastic for about 5 minutes until they saw some mud. Injecting a huge amount of fun into autumn/winter riding for me and they handle well on the road too. Very satisfying thrum at speed on smooth tarmac and I've yet to find any terrain they can't cope with. Now my only ride hazards are tree branches, deer, and squirrels. Gonna need a bike wash though...

Also, it's quite a revelation being able to run 40psi and not have the tyre roll off the rim or snakebite a tube. Good fun cornering at speed on these tyres, feels a bit like drifting in Mario Kart! Very definitely need to set up your line but I seem to be able to lean more than on road tyres (on tarmac). Reminds me of my Raleigh Grifter!

I'm pretty sure the local mountain bikers (there's a bike park where I ride) are looking at me funny, and I suspect at the bottom of this rabbit hole is a hardtail trail bike, but its a huge amount of fun. Come spring and I can go back on skinnier rubber - probably Byway or Horizon or one of the Compass tyres.

Regarding CO2 and latex sealant - I did a bit of googling and found out that the main reason that you don't want to use CO2 and latex sealant is due to the cold-shock of the CO2 that makes the latex start to polymerise (turn into little balls).

So, apparently (untested by me so far) you can get better results if you place the valve at the top of the wheel (i.e. 12 o'clock position) and let the sealant pool at the bottom. That way, the CO2 should warm up a little bit before hitting the sealant.

My tubeless record:

I have 2 bikes both set up tubeless, both using Hunt's 4 season disc wheels.

One is shod with IRCs excellent roadlite 25mm tyre and has done 4300miles. The other with Schwalbe S-One (now the G-One I believe) 30mm and has done 3600miles.

Fitting was relatively straight forward using Tesa rim tape and the soapy water on the rim method, I inflated them using an Airshot tubeless inflator. I use the Milkit tubeless valves which allow me to check/top up the sealant without having to fully deflate the tyre every couple of months.

2 punctures (1 in each wheelset), the first was an unwound paperclip that had worked it's way into the tyre once removed the puncture sealed perfectly and hasn't caused any issues since. The second was a bit more tricky and needed the application of a tyre worm, again once in and the tyre re-inflated it hasn't given me any issues.

To be honest my experience of tubeless has been nothing but positive, so far no standing by the roadside trying to shove a tube in where it won't go nor have I had a puncture that won't seal. The worst experience I've had is having to peal dried sealant of several bits of the bike after it sprayed all over the place before I could get the worm in.

My tubeless record:

Hutchinson Intensive lasted 5 years on the font wheel. 2 punctures that I am aware of: 1st without sealant (a stupid experiment), tube in roadside and carried on, repaired with standard patch at home; 2nd 4 years later, a piece of wire that worked itself between the rubber tread layer and the carcase, which I only noticed when I got home after a day out as there was a bulge on the tyre. The tread was so thin at that point that is came away in pieces when I started investigating. A bit of a pig to mount when new but the Spa Cyles video method helped out, no need to resort to levers and managed to mount the bead back on at side of road in winter cold too. As it got older became easier to mount.

Bontrager R3 TLR that only lasted a year as sidewall slashed. Very easy to mount.

Pro One that has lasted for over 2years: no punctures that I am aware of so far. Easy to mount.

Huntchinson Fusion 5 All Season got 1 puncture (about 4-5mm, glass slash) that the sealant failed to plug above about 40psi. Has been repaired at home (tube in at roadside etc.) and is back on duty at the front. Fairly easy to mount.

All on Stan's Alpha rims.

The seating thing is the only part that has ever caused me grief, but now I just slosh in some sealant and shake about a bit and then give it some with the track pump. Works every time. Might get the odd dribble of sealant escaping in that process but nothing major. I keep thinking about getting a tank but as this works with my setup I probably won't.

I know it's off topic to talk about the benefits of tubeless here but the main thing for me is the comfort and feel. I had Gatorskins before, that I loved for their toughness, but now I know from experience that they are seriously wooden in comparison to any of the above. Particularly at the +100psi I was running them at. I am around 80kg, so run around 80-85 psi on the front 25mm tyre and 85-90psi on the rear 27mm (both measured, both different brands... I know, that might offend some ).

).

It's quite easy to Make Your Own Tubeless Inflator from a 2 litre drinks bottle. Took me about 30 minutes and works beautifully!

Tried tubeless on two different wheelsets sets and 3 different tyres. All failed.

The first was on Bontrager rims with Bontrager TLR tyres. The bike shop really struggled to fit them - took a lot of time and they were clearly frustrated. Soon after, I had a major puncture which released all of the sealant. I tried fitting a tube but could not get the tyre to reseat. Ride over and wife called. Tyre binned.

Second was with the above rims but with Schwalbe One tyres. Super difficult to fit and like the TLR's - heavy. They lasted about 1500kms before I flatted. Found that sealant had hardened after a couple of months.

Gave up for a while with tubeless but then tried Schwalbe pro-ones on new Reynolds carbon rims. Very difficult to fit even with a new tubeless track pump, although managed to seat one tyre after many attempts. Had no luck seating the other tyre with the pump or at the local service station so went to local bike shop. They used compressed air like the servo and managed to finally seat the rear after several attempts and by removing the valve core. Soon after I decided to sell the rims. Front tyre was difficult to remove but got it off. The rear required a vice and a blade to cut it off the rim (carefully). How I was ever going to get it off on the side of the road is anyones guess.

Until there are major changes, tubeless is a major fail in my personal experience.

There is a common factor in your troubles.

Two punctures in the first two miles of last year's Ride London made me go tubeless. Hunt kindly installed the tyres onto my new road bike wheels and I have not looked back. I now also have them on the Kinesis gravel bike with 30mm tyres and have run them at 30psi across some of the roughest parts of Dartmoor - I recommend topping up before going back on the road though as descents were a bit sketchy at that pressure!

Pages