- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

How to trim a carbon fibre steerer tube 04

How to trim a carbon fibre steerer tube 04How to trim a carbon fibre steerer tube in 5 easy steps

You'll need to trim your fork steerer if you're fitting a new fork, building up a bike from a frame, or have just decided you really don't need that spare inch that's above the stem. Here's how.

Carbon is the go-to material when you're looking for strength, rigidity and light weight. Those happen to be the exact attributes required of a road bike fork. All-carbon forks used to be the preserve of high-end bikes, with aluminium steerers on entry-level models, but even sub-£1,000 bikes are now coming with carbon steerers. Whether a steerers is alloy or carbon the method for trimming it is broadly the same.

Our guide below shows you what we believe is the best method to trim a carbon fibre steerer. We've included a list of the tools and materials that you will need to complete the job and in some cases where you can buy them. If there are others that you prefer then feel free to let everybody know in the comments.

Health warning

Because the fibres are so thin, the dust produced by cutting and filing carbon fibre composites contains very, very tiny carbon particles. These can irritate the lungs and skin. You should therefore wear a well-fitted face mask to avoid inhaling them, use gloves, and keep skin covered that might be exposed. You should also work in a well-ventilated space away from electrical equipment. Carbon fibre is conductive; you don't want it in your favourite mp3 player or fan heater.

Tools & Materials

Carbon specific hacksaw blade

Steerer tube cutting guide

Tape measure

Masking tape (not pictured)

Step 1: measure, measure and measure

The first thing you need to do is determine exactly how much of the steerer you need. Now, it's common, in the heat of the moment of getting a flash new fork, to see yourself all flat backed and aero, slicing the wind like Cavendish in the last fifty meters of a sprint.

It's tempting to slam the stem on to the headset top cap to get that position, because it looks neat, but cutting your steerer as short as possible can cause issues if you later realise that you're not Cav, on account of how you can't touch your toes and all.

You can't stick the off-cut back on. Better to be honest with yourself. It's less embarrassing and cheaper in the long run.

In short, it's better to have and not need steerer tube, than to need and not have.

I measured up for a fairly flat FSA K-Force stem, fully slammed. However, I left myself an extra inch and a half just in case. Just as well, because in the end, after fifty miles of running in, I switched to a shorter, taller Truvativ T40 stem with a 5mm spacer under it. Had I chopped just for the FSA stem in flat mode, I'd have been stuffed.

Measure, re-measure, check, re-measure again, check again. Put it back in the frame, re-measure. Be honest. Measure a last time. You're now thoroughly ready to chop 45-quid's-worth of carbon from your fork's steerer tube.

Step 2: Mark the steerer

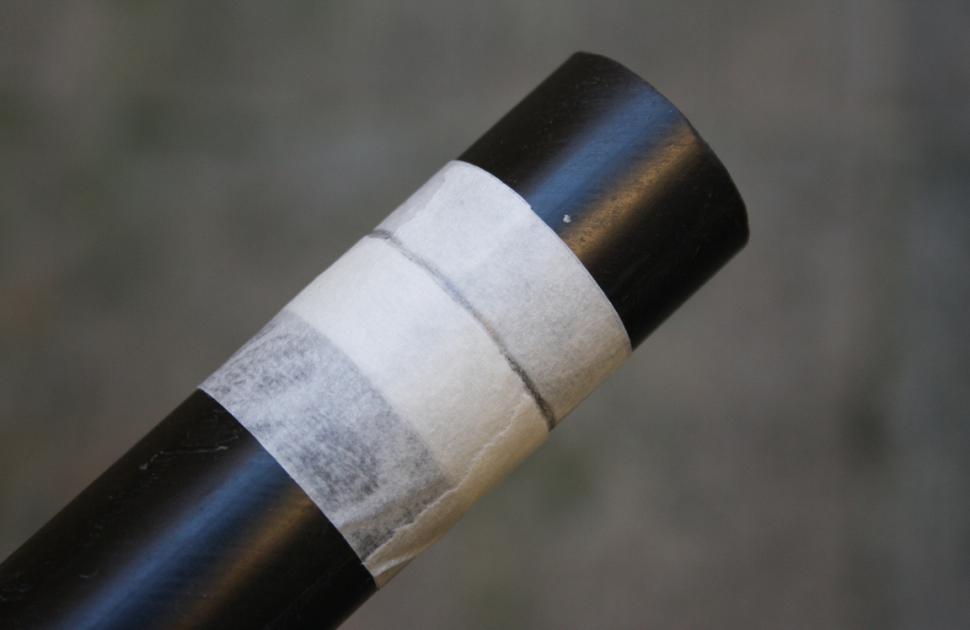

When you've made the final measurement, mark the spot with a wrap of masking tape. This will help ensure the edges of the steerer do not fray during the cutting process (remember carbon fibre is just posh cloth and glue). I make the wrap exactly centered over the cut mark and mark it with a pencil. I then put another wrap to one side with the edge right on the cut line, for no good reason other than habit.

We are using an adjustable saw blade guide. This particular model from Park Tool has a regular slot on the right for alloy steerers (which would use a narrower conventional hacksaw blade). We are using a specific carbon fiber cutting blade which is wider than the toothed version for cutting alloy - hence the wider slot on the left, which is the one we'll be using.

Step 3: Fit the saw guide

Slide the steerer tube into the cutting guide and look down into the cutting slots to see the pencil cut line. Line the pencil mark up directly with the wide slot.

When you've got the cut line lined up, tighten the clamp. The clamp has rubber shoulders, so it won't hurt the steerer tube when done up tight. You want it fairly tight because it mustn't slip.

This is a the carbon specific hacksaw blade. Instead of classic hacksaw jagged teeth, the blade is coated with a fine coating of cutting grit. You can get away with cutting your carbon steerer tube with a conventional blade, but it's not ideal.

Step 4: Cut the steerer

Ideally you'd hold the cutting guide clamp in a bench vise. However, the cutting guide precisely controlling blade position means its technically possible to get away without a vise. I don't have a vise at home and manage happily with the guide alone.

Step 5: Tidy the end

Because the cutting guide keeps the blade so well centred, the finished cut will be pretty well ready to go. It's good form to use a fine file to radius the outer edge and ensure there are no burrs that will catch on the stem and headset internals when you come to fit it. Only do what's necessary and remember carbon dust is nasty stuff. Hoover it up when you're done.

The finished item. The steerer is now the right length and cleanly trimmed and finished.

Latest Comments

- brooksby 2 hours 29 min ago

I trust that you also encourage motorists to buy white or yellow cars and to shun vehicles the colour of a wet road?

- stonojnr 2 hours 48 min ago

nah they just read the question as do you always not leave the recommended 1.5m when overtaking cyclists. I know people overestimate their...

- David9694 2 hours 55 min ago

Worcester hospital parking 'horrific' as petition handed in...

- stonojnr 2 hours 57 min ago

Ive never seen the figures broken down by who reports them, you can kind of infer things from stats, like Ive seen them break it down as careless...

- Hirsute 3 hours 24 min ago

Are you going to answer?

- wtjs 3 hours 36 min ago

No more of this! HP will turn to stone!!

- wtjs 3 hours 45 min ago

I'm using 700c, 9-speed 46/30 with a ?-34 cassette for all my cycling including the Bob trailer. It's about right - I can't get up everything on my...

- Bmblbzzz 5 hours 51 min ago

"A brutalist interpretation of a road" So true. Grey markings on grey paving slabs surrounded by other grey paving slabs...

- Simon E 5 hours 35 min ago

Driver in a Citroen travelling at 70mph crashes into the front of a house in Canterbury Road, Faversham at 5.30am on Sunday....

- arichman 6 hours 24 min ago

Somewhat confusingly, Velocio includes both a fit and a size chart, and says to use the fit chart (which uses height and weight) as the guide for...

Add new comment

33 comments

IceToolz make a really nice tool for deburring the inside and outside edges of the cut. It works brilliantly http://www.icetoolz.com/ec99/rwd1111/product.asp?prodid=16B1.

Re the specialist carbon saw blade, any ceramic tile style hacksaw blade works. These are preferable to regular blades because the teeth of a regular blade hook the carbon strands and try to pull them out of the resin as they cut. Much better for the overall integrity of the carbon to abrade your way through with the tile saw style blade. You can shim the cheaper saw guides out with a bit of coke can or the like to make the gap wide enough for such a blade.

2 jubilee clips set a hacksaw-width apart, and a fine-toothed hacksaw. Works every time

I've done a few now - new forks in used frames. I mark around the steerer and cut with the cut off disc on my angle grinder, usually while still on the bike. Glasses only (incredibly little dust created) worn. Never had a problem

So.... It's a tube. Plumbers deal with tubes all day. They use pipe cutting tools. They are deadly accurate, cut cleanly and you can be as gentle as you like.

I have no idea why saws as used on steerer tubes. That's the way I was taught - makes no sense to me.

I've done a few carbon steerer tubes and just use a fine toothed hacksaw and the Planet-X cutting guide. Does a perfect job every time, just avoid the dust.

For all those vacuuming carbon dust, make sure the vacuum has a HEPA filter on it otherwise a lot of the finest (and nastiest) dust will find its way back out of the vacuum.

This is listed as suitable for fibreglass and looks identical to the more expensive supposedly "bike" specific blades.

https://www.toolstation.com/tungsten-carbide-grit-hacksaw/p48146?utm_sou...

I got a new stem last week and it has a 5mm stack height taller than my previous stem, which means to fit it there's no space for a spacer above it. It fits perfectly and looks totally flush, but I'm not sure if that's safe or not. Anyone have any idea? The new stem is a Zipp Sl course and has it's own top cap. All seems to fit fine. Haven't ridden it yet. Have visions of the front end exploding

Don't think it will explode!

If your stem has taken up the 5mm previously provided by your spacer above it, and it was already set up correctly (ie the top cap sits several mm above the top of above the top of steerer tube) then all good.

the two things to be aware of, are:

1) the contact area between stem and steerer tube must be sufficient to ensure an even pressure across it's area (you've probably still got this with only a minor 5mm change) and

2) the top cap has enough height, as above, to allow the screw to bite properly into the centre bolt and tighten it up

1) is less of an issue if your carbon steerer has a bung / expander bolt in it anyway

Worth checking what is advised by your fork manufacturer in terms of max number of spacers under the stem, as well as including a 5mm one above, as mentioned previously.

There's nothing wrong with wetting the saw blade to reduce dust production either.

aluminium tube- angle grinder+ file

Carbon tube- angle grinder, vacuum+ file

Angle grinder?! Really?!

Errrr....

Using aluminium as a cutting guide (old stem, spacer, etc) may lead to the saw chewing up the guide and the cut not being straight. I'd go for something made of steel, eg the proper tool.

Good call about the gloves, mask and glasses.

I have found that a 10mm spacer taped into place makes a usedful guide.

Mask, gloves and glasses. Extra careful if you wear contacts, I knew someone who had some quite nasty eye problems after accidental exposure to fibreglass dust in their office.

The steerer tube that came on my new fork was crazy long - I'm sure no-one has a head tube that long!

A bike shop took 2" off it for me when they fitted the crown race, but now I've had it for a while, I'm confident it can lose another 15-20mm and still leave me with a bit to play with. Not ideal, but I really don't mind a bit sticking up on a road bike.

Unfortunately, because of the health issues with cutting carbon, my local bike shop seems to have a policy of once they have enough bookings, they'll start the extractors up. As the only person I'd trust to do it for me is fully booked, I've bought a carbon cutting blade - £8 online from Ribble - and will chop it myself with the hoover turned on.

Couple of jubilee clips should do the job as a guide.

FFS! Any sharp fine tooth mitre saw will do the job ! Why do folks these days over spec everything !

Agreed

Because carbon isn't steel or aluminium. The cut edge will fray if you cut it wrong. And because this can happen:

https://twitter.com/bguyot1982/status/1173298419894554628

The steerer is a highly stressed part:

https://www.velonews.com/2013/08/news/cervelo-founder-calls-for-industry...

Planet-X do something like this Park Tool guide (Jobsworth Fork Steerer Tube Saw Guide) for £14.99. Not sure if it has a guide wide enough for carbon specific blade though, might just be for usual steel blade.

Have also seen one for aero seat posts/steerers.

Yeah, but how long have they been around?

It's not wide enough for carbon blades. Looks like you can take it apart and add a couple of washers to adapt it.

Only needed it done twice and both times I've been charged a mere £15. Cheap for peace of mind, no tools needed and have comeback against someone if they cock it up. It's the only job I won't do.

They haven't been around that long? 1963?

Blimey. New hacksaw blade and an old stem clamped to steerer as a guide to cut against.

That, probably expensive, blade looks like an ordinary tile cutting blade.

I don't know where park tools came from but they haven't been around that long and there's nothing special about most of their stuff. I'm used to every US site plugging them but it's getting a bit much here doing it over here too.

I have a new carbon fork on order from my local shop (idiot pedestrian, busted fork), and they offered to cut it to size. Foolishly declined the offer; I'll be beavering away with a tape measure tonight, and back in tomorrow to eat some humble pie and ask pretty please if they could take a little off the top.

Some things are best left to the experts, or people more expert than me anyway.

Also, depending what stem you have, if it is completely flush and you decide to change brand you may be limited by the stack height. Not an issue for all people as well but if you decided to change your position in the future you may benefit from the adjustment

Was actually thinking to put the 5mm spacer under for a bit to get used to them stem that low. GIve myself a little relief.

You should always have a small, usually 5mm, spacer above the stem, so the shop did it correctly. The reason is that there is less likelihood of crushing the top of the steerer with the stem clamp if you are not clamping right on the end of it.

Pages