- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

Viner Maxima RS: we get our handbuilt superbike

Finally, I've got my hands on our brand new Viner Maxima RS for review on road.cc, and it's looking amazing. Excited? Oh yes.

Okay, so here’s the story so far… All Maximas are made-to-measure so I’ve had a bike fitting in London courtesy of Guiseppe at Velo Solutions, and the frame has now been handbuilt by Marco Bertoletti in Bergamo, which is just up the road from Milan. If you’ve not looked at those two articles, you might want to give them a quick read now – they’re beautifully written and things will make a lot more sense.

Now we need to get the frame built up. The simplest thing would be to have the frame air-freighted over to the UK, get out a catalogue and select the bits to go on it, and have them sent over too… but where’s the fun in that?

Peter from Viner had a better plan. Get on a plane, fly to Italy, pick up the frame from Marco, then head over to component manufacturer Miche and collect the shiny bits from there. Okay, the old carbon footprint is a whole lot bigger doing it this way and I’d have to put up with a couple of hours of RyanAir’s particular brand of hospitality but… well, it sounds much more of a laugh. Where’s my passport?

So that’s how I found myself at Marco’s workshop. And when I say ‘workshop’, that’s exactly what this place is. It’s a little industrial unit at a push. Factory would be going too far. No belching chimneys, no clocking in machines, and no dirt on the floor. We’re talking small-scale manufacture here in the Italian craftsman tradition. There must be, ooh, half a dozen people on site, along with the biggest, loudest guard dog you’ve ever seen. Mass production, it ain’t.

I won’t go into detail on the frame building process, we’ve already covered that, but I will show you some of my holiday snaps – just the interesting ones. This, for example, is the guy cutting out pieces of prepregnated carbon fibre to form the tube joints. Yep, he does it by hand with a big pair of scissors before bonding them in place. I wasn’t expecting that.

This photo is the carbon tube that’s used for the down tube of a Maxima RS. It looks pretty lightweight and flexy, yes? You’re 50% right. It weighs nothing but you try to twist it about or even squeeze the sides in and you’ll get nowhere: it’s as tough as the Dolomites.

And this pic is Marco showing off the autoclave – the machine that bakes the frames under pressure to form the joints. It’s a serious bit of kit.

Marco makes bikes other than Viners too, including titanium models for Legend. See the head tube on Il Re (The King, in English)? It starts out life as a hefty pipe of ti before he machines it right down to the lightweight, precision piece that actually gets built into the frame.

Incidentally, all the joints on the titanium frames have to be produced in the absence of air to stop impurities getting in there, so the frame goes into a sealed chamber and all the work is done via gloves that reach in through the walls. It’s an incredibly labour-intensive process.

Anyway, we’re getting sidetracked. Back to the plot… Apart from having a shufti around and a nose at the goods, I’m here to pick up the carbon Viner Maxima RS frame, and that’s exactly what I do. It’s great to finally get my hands on the finished article and it’s looking lovely (the pic shows Guiseppe with the frame back in London). All clean lines and gorgeousness with a beautiful matt finish. Well, judge for yourself. Pretty, huh?

It’s funny to see the lengths of tubes that make the frame all racked up on one side of the workshop and the complete article on the other. And it’s cool to meet the guys who actually do all the work, even though they don’t speak much English and I speak even less Italian (grazie, arrivederchi, various types of pasta… that’s it). They’ve done a great job. I can’t wait to get out on the roads.

I’m not going to be able to ride it as it is, though. Time to find some components to fit on this bad boy, so I say my grazies and arrivederchis (I couldn’t think of a way to shoehorn vermicelli into the conversation) and hit the road.

Because Viner are one of very few brands who still use Italian-made frames, it’s only right that we set it up with Italian parts, so Peter and I are heading over to see Miche in San Vendemiano. That’s up near Treviso. No? Top-right, basically.

Miche is a bigger company, but it’s still pretty small in the overall scheme of things with just 40 employees. It has been around since 1919 when Ferdinando Michelin began to produce bikes and components, but the Michelin name was already taken – you might have heard of them; they make tyres, apparently – so it was shortened to Miche.

These days the company makes wheels, chainsets, sprockets, pedals, bottom brackets, brakes… They don’t make shifters or mechs, though, so they team up with compatriots Campagnolo to provide complete groupsets.

Miche’s top-level group is Supertype, a combination of their own high-end kit and Campagnolo’s Super Record. This lovely, shiny stuff is what’s going on the Maxima RS. Oh yes, this is going to be one special bike when it’s up and running.

Like many Italian firms, Miche is still family run. Ferdinando’s son, Italo, is company president. Pushing 90, he still puts in a seven-hour day while Ferdinando’s nephew, Luigi, is in day-to-day control. We met them and, along with sales director Valter, they showed us around.

If you’re skeptical that any components get produced in Italy these days, you’re wrong. See this?

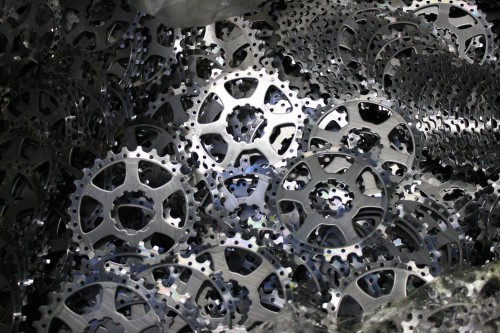

That, believe it or not, is a few thousand sprockets. Well, it is by now. The reels get fed into one side of a machine, and out of the other side come these…

Thousands of them. Tens of thousands. All shiny and perfectly formed. Magic. Or clever engineering. One or the other.

Nearby, there’s a machine that’s making chainrings out of solid sections of metal. In goes the block, the CNC machine goes to work shaping and milling, and out comes the finished object… or not, in this case. This one didn’t make the grade so it goes in the scrap bin.

Some of the machines look almost alive. Out comes the neck, it peers at the row of sprockets for a second, plucks one up with its beak, takes it back to its lair, performs some complicated jiggery-pokery (it’s a technical term), and then spits it out into the finished pile. It’s hypnotic! I’ll tell you what it looks like with all those staccato movements: a velociraptor from Jurassic Park. A bit.

Other machines are building hubs, pedals, cranks… all sorts. It’s not all automated, though. The spokes are put into the wheels by machine but they all roll down to a guy with a wheel jig who trues them up by hand. The tolerances are ridiculously precise, and once they are spot on, they get sent on their way.

Aside from the manufacturing, the quality gets checked all the time. Miche have a bit of an obsession with quality – which makes a lot of sense if you’re an Italian brand competing against the Far East where production costs are lower.

Miche don’t, for example, produce road clincher wheels with carbon braking surfaces because they reckon the pressure of the tyres means you can’t rely on them. And while they’ll try to shave weight off their components where possible, they won’t do it at the expense of stiffness.

“Weight is a factor,” says Valter, “but there’s no point producing an 800g wheelset if it’s got the performance of chewing gum when you get on the road.”

You can’t argue with that. The testing lab is full of products getting put through their paces. There's a chainset, for example, having a 180kg force applied to it in a flex test, then removed, then reapplied… That’s at least double the weight of most riders, and the bottom bracket is fixed, unlike on a bike where it’ll move around. If it survives 180,000 cycles, they’ll put it into production.

Another machine is doing a similar job on a hub, applying forces via a couple of spokes, and two pistons are firing alternately to rock away at a seat post’s saddle clamp.

Miche also have their own destruction test rig for their carbon wheels which is a lot of fun for someone. Basically, the UCI say that in order to be permitted for racing, a carbon wheel has to remain in one piece when a 100kg weight hits it at 10kph. Obviously, that’s going to destroy the wheel. It’s just that bits aren’t allowed to go flying off and smack into unsuspecting competitors… which seems fair enough. An alloy clincher gets sacrificed in the way of demonstration. Youch!

It all seems to be working. Miche produced 25,000 wheels last year and got 20-odd back with problems. That’s a result. Much as they like their wheels, they really don’t want to see them again once they’ve been sent out of the factory.

The factory tour over, I collect the Supertype 11 Carbon groupset from the Miche guys. We’ll go into more details on the equipment when we test the bike but here’s what it looks like: stunning. There’s carbon everywhere with red and white graphics, just like the frame – we think these things through, you know. This bike is going to look amazing.

More grazies, more arrivederchis and we hit the road again – we’re bound for the airport laden down with Italian goodies. What happens next? I drop everything off at Le Beau Velo bike shop in Shoreditch, London, and they assemble it.

Then, once it’s put together, I arrange to meet Guiseppe from Velo Solutions bike fitting service – who originally measured me up for the Viner a few weeks ago – at the shop for a final fitting. We did that last weekend.

The bike is setup on a turbo trainer, I climb aboard and Guiseppe checks that everything is exactly as it should be. I pedal away and await the verdict. I’m a bit nervous, to be honest. Imagine if it’s not right after all this effort. That’s a hell of a lot of time and energy to get a bike that doesn’t fit. I needn’t have worried.

“Molto bene,” he says. “Very good. Perfetto’’. Guiseppe is a happy man. Like Hannibal out of the A-Team, he loves it when a plan comes together.

My arms are nicely bent rather than locked out, my back curves gently without any strain and I can get my torso flat without any trouble, and I’m not reaching with my toes as I pedal… I’m immediately comfortable. I’m allowed to raise the saddle by 2-3mm if I really want to after a few rides but I’m banned from making any big changes. This position is molto bene. It’s a job well done.

So, that’s where we are. The Viner Maxima RS is up together and looking beautiful. And, even better, we have it. Exciting! Now it’s time to get the miles in. The proof of the pudding and all that. I’ll let you know how we get on soon.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- don simon fbpe 7 min 37 sec ago

I can't work out whether this is a complaint about being pushed down the list or a huzzah for the plucky Brits trying to kick Putin's ass and fight...

- Rendel Harris 51 min 48 sec ago

I can't speak for this company but I know a couple of people who have contacted manufacturers (one through their LBS, one direct) and asked for...

- chrisonabike 2 hours 25 min ago

That sounds most unfair! They'd been "pro-social" (to drivers) by blocking the footway as well as part of a lane!...

- Rendel Harris 5 hours 56 min ago

I'm afraid that has been a really worrying change over the last few decades: thirty years ago just shouting at a thief to let them know they'd been...

- hawkinspeter 6 hours 27 min ago

I do carry a cheap TPU tube for emergencies, but the Dynaplug is so much quicker and easier than needing to remove wheel/tyre etc. You just get the...

- Rendel Harris 7 hours 6 min ago

March 21st, 1967: birth of Adrian Chiles.

- chrisonabike 8 hours 33 min ago

(This is rather OT now, but...)...

- chrisonabike 9 hours 14 min ago

That's old hand! You really want a hand with integrated display.

- David9694 10 hours 42 min ago

It made a hole and police are looking into it.

- Rome73 13 hours 3 min ago

Yes, I agree. These huge vehicles scare cyclists and discourage cycling. I would not let my children cycle some of the routes I regularly cycle...

Add new comment

2 comments

I can't wait to here how the Viner Maxima performs? Will this Italian handmade bike exceed the performance of top end far eastern frames. Having read all of Mat's articles about this process I'm guessing yes.

Looking good Mat. Road report when you first take it out mate? thanks ...