- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

rotor-uno-3

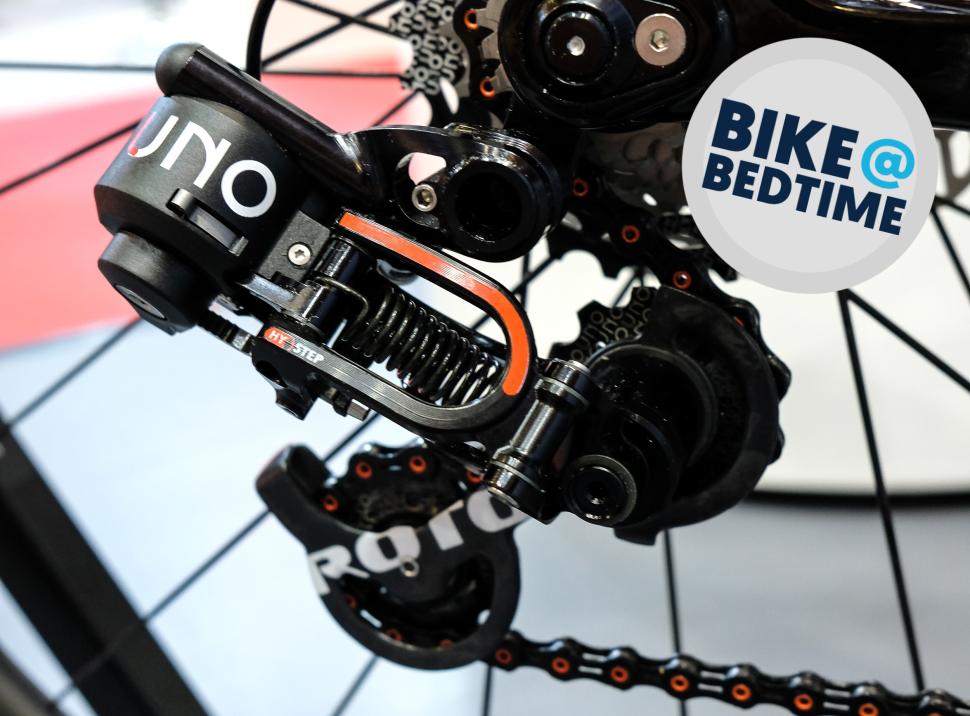

rotor-uno-3What happened to the Rotor Uno groupset with hydraulic shifting?

Tonight’s Bike at Bedtime isn’t a bike; it’s Rotor’s Uno groupset which offered both hydraulic braking and hydraulic shifting. Although Uno doesn’t exist any more, the tech morphed into the 1x13 groupset (that’s the name as well as a description), which remains in Rotor’s range.

The groupset market was hotting up back in 2015 when Rotor first revealed photographs of Uno. There had been plenty of rumours that the Spanish company best known for its cranks and non-round chainrings was working with hydraulic brake and mountain bike suspension fork specialist Magura to develop a new groupset, and that proved to be the case.

“Uno will publicly stake a claim as the first complete road groupset with hydraulic actuation shifting and braking,” said Rotor. “By partnering with Magura to produce Rotor Uno's brake systems (both disc and rim), Rotor will leverage more than a century's-worth of expertise in hydraulic brake systems.”

The new groupset had been six years in development.

“Our initial idea was to improve upon existing shifting systems; we knew that our system was a small step forward with its increased precision compared with other cable-actuated systems but we still suffered the same disadvantages of those systems, like friction, devolving inconsistent force over time, and other inconveniences,” said Pablo Carrasco, co-founder and chief innovation officer for Rotor.

“We knew that disc brakes for road were about to become a reality and we challenged ourselves to further the concept and apply hydraulics to actuate shifting as well.”

Rotor said that the advantages of a fully hydraulic system included smooth activation and low maintenance. Also, unlike with electronic groupsets from Shimano, SRAM, and Campagnolo, there were no batteries to worry about.

> Hands on: Rotor Uno groupset

With a hydraulic system, you can run the hose wherever you like and make the bends as tight as the hose outer will allow with no loss of shifting efficiency. Once the system is set up, it should be entirely fuss-free. There are no cables to adjust, and no holes for water to get into and ruin everything.

Hydraulic shifting also offers the potential for multiple shifting positions. You can splice two hoses together and have a shifter at the end of each one. That's good news if you have a time trial setup, for example.

With Rotor Uno, the shifting and braking systems were entirely separate, each having a master cylinder in the lever hood. Uno used Magura's Royal Blood mineral oil; all the hydraulics were produced by Magura and the groupset used Uno-branded Magura disc callipers and Magura's RT8 hydraulic rim brakes – disc brakes were yet to dominate the road market back in 2015.

Uno was a 22-speed (2x11) groupset and changing gear was similar to SRAM’s DoubleTap system. A short click dropped the derailleur down, with a longer push shifting the other way. The rear derailleur could move the chain up to four gears at a time (an adjustment screw in the lever hood allowed you to set the maximum number of shifts you wanted from a single push) while the front derailleur had four positions: two trim positions for each of the two chainrings.

We got our hands on Rotor Uno for the first time at the Eurobike show in 2015 but we only played on demonstration units, we weren't able to take it out on the road.

We found downshifts on the rear derailleur to be very positive but the upshifts a bit less so, especially when set up for multiple shifts. The front derailleur gave a pretty chunky click going both ways. These were still prototypes so we couldn’t say much other than that it appeared to work.

MTN-Qhubeka pro rider Daniel Teklehaimanot was then spotted testing a Cervelo R3 Disc fitted with Rotor Uno components, but then things went a bit quiet for a while – publicly, at least – until it was announced that the groupset would make its first appearance in the pro peloton with the WNT-Rotor Pro Cycling women’s team in 2018.

Things changed in 2018, though, when Rotor started shouting about its single chainring 1x13 hydraulic groupset (below) which used the same shifting technology as Uno with a 3mm hose. This was before Campagnolo had introduced its 13-speed Ekar gravel groupset.

> Video First Look: Rotor 1x13 – all you need to know about Rotor's latest hydraulic groupset

The derailleur had been pretty radically redesigned, though. For a start, it was designed to work across all disciplines, so it needed to be tough enough to withstand the rigours of mountain biking.

Gone was the open design of the Uno derailleur, with the new mech using a closed alloy body for better protection of the shifting mechanism from the elements and other sources of damage. The cage and parallelogram had been redesigned with a 42T capacity to work with a 10-52 cassette.

> Rotor 1x13 was officially launched in 2019

Still, Rotor's hydraulic shifting lived on, and continues to exist because Rotor 1x13 is still available in road and mountain bike configurations – but have you ever seen it out in the wild? Uno isn't part of Rotor's current range now, having made way for 1x13 in 2018, although you can still find it through some retailers.

When we rode an Argon 18 Dark Matter fitted with the Rotor 1x13 hydraulic groupset five years ago, we weren’t really impressed by the shifting.

“Ultimately, it falls down on the shifting performance, which just isn’t as good as Shimano, SRAM or Campagnolo,” said Dave Arthur.

“The key issue to my mind is the lack of a defined hard click, or thunk, when you’ve moved it the prescribed amount to initiate a gear change.

“The reason for this vagueness is simply because the indexing is built into the derailleur, not the shift lever like other groupsets. There is a click but it’s barely noticeable, either through your finger or ears. You really have to feel for the soft ‘indentation’ that marks the gear change.”

With the prevalence of high-end electronic systems today, do you think there’s any chance of hydraulic shifting gaining a foothold, or has it missed its moment? We’d be interested in your thoughts.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- richliv 0 sec ago

I thought I would read that DT article before commenting. It wasn't as rabid as expected and apart from the obvious inaccuracies on KOM speeds ...

- VIPcyclist 1 hour 8 min ago

I remember, 40 years ago, telling my dad, who was a Daily Telegraph reader, he's now 'graduated' to the Daily Mail, that not everything in the...

- mattw 5 hours 31 min ago

I think, along with others judging by the comments, that the cycling group have the wrong end of this - in that the travel conditions are similat...

- john_smith 6 hours 6 min ago

Actually, yes. Hundreds of thousands.

- chrisonabike 7 hours 53 min ago

Meanwhile, in the Netherlands......

- andystow 13 hours 14 min ago

I quite like the look of the tee, it would make it really hard to tell whether or not I had just come from a paintball fight.

- Simon E 13 hours 16 min ago

I fail to see why that is any more valid. The markets are not comparable, my point was about how some brands can sell overpriced, inferior products...

- David9694 13 hours 31 min ago

second home owner gets £60 parking penalty in Cornwall ...

- DoomeFrog 13 hours 59 min ago

The Best Overall are, by definition, also the best under £100?

Add new comment

8 comments

typo - 2025 instead of 2015....paragraph 9......

Seems that this was not quite good enough but also became redundant with the emergence of wireless / electronic shifting. Wire routing, reliability, lack of maintenance etc all undermining its case, added to the fact we probably trust electronics more than hydraulics especially when the later was a non mainstream player.

Sorted. Thanks.

It certainly arrived several years too late... but it would have failed anyway, the lever feel and performance of the whole system was just awful. For all their talk of understanding the drawbacks of mechanical systems they managed to design a hydraulic version that was worse at all of them except cable stretch. Heavy, sluggish, spongy levers with no tactile shift click at all.

Never mind the one piece cassettes and their habit of shearing in half because they were only supported on the splines at one end...

Let's not forget Shimano's compressed air shifting system...

First I've heard of that. Goes off to investigate...

https://www.ebay.com/itm/281325916610

Oh wow. I think we need an article on that

A bit more about it here

https://road.cc/content/feature/cycling-tech-innovations-never-took-off-...