- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

NuVinci CVT hub gear

NuVinci CVT hub gearNuVinci: no gears, but all the gears you need?

Hub gears are big in the world of commuter bikes these days with everything from three to 14 speeds available. The benefits to the rider are straightforward: the chainline is simple and fixed, which means longer chain life and the ability to enclose the chain for even lower maintenance; and the gear mechanism itself is protected from the elements too, meaning there's less tinkering to be done there as well.

There are downsides, too, however. The internals of a hub gear are fairly complex, and the more gears you get the more complex they become. Also, hub gears tend to be eight speeds or less (the exception being the pricy Rohloff SpeedHub) which means some fairly big gaps between gears.

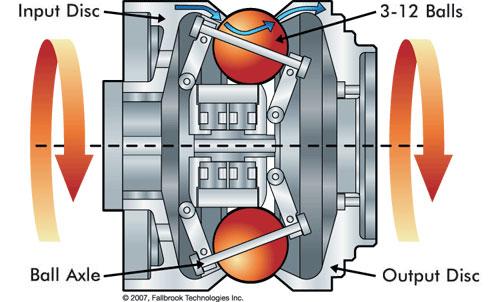

Enter the NuVinci hub from Fallbrook Technologies. The NuVinci is a Constantly Variable Planetary gear (CVP) meaning there are no fixed ratios: you control the hub from a twist grip shifter as you normally would, but instead of selecting gears the shifter moves a ring of rotating balls which continuously adjust the relationship between the input and output of the hub. So, within the limits of the NuVinci, you can have any gear ratio you want. You can also change gear whether you're pedalling or not – the same as a standard hub gear – and the internals are much simpler than a gear-based hub. The ratio range of 350% is comparable with an eight speed hub, though well below the 520% or more you can get from a derailleur setup, or a SpeedHub.

There's no actual contact between the balls and the drive plates; the hub is filled with a torque fluid which momentarily solidifies in the small gap between balls and plates to transfer the drive. You need to change the fluid every 35,000km or so but other than that there's no maintenance, and because there are no gears, there's no indexing worries either.

Confused? so were we, a bit. But here's a handy video from Fallbrook which explains the system a lot better than we just have...

Is this all too good to be true? Well, a little bit: you won't be fitting it to your slinky road mount any time soon. The hub itself is a real entity, the first units rolled off the production line in December 2006 and you can have the kit (hub and controller) for a very reasonable $449. Its main application at the moment is defined by its weight: a hub weighs a portly 3.8kg, so the main avenue for bike use is in commuter/cruiser bikes. It's too heavy to be used in a road or mountain bike, but Fallbrook are confident that later versions of the hub will push the weight down to a point where it's competitive with a more standard setup.

There's also the question of efficiency: The bike FAQs for the Nuvinci state that, "As a traction drive transmission, the NuVinci CVP will be less mechanically efficient than direct drive transmissions" but are unclear as to what those efficiency losses might be. In the world of commuting bikes this isn't such a big issue, but it might limit the use of the technology on bikes in the long term. Fallbrook are keen to emphasise, though, that although the technology is well suited to bikes it's not limited to them: they're also marketing the NuVinci as a solution for light electric vehicles, outdoor power equipment, agricultural equipment and wind turbines, among others.

Assuming that the weight and efficiency questions can be answered in a road riding concept, however, the hub throws up some fascinating possibilities. because it's not indexed and the control is simply a rotating axle, it's a prime candidate for electronic control, and you could mate the hub up to a cadence sensor to allow a rider to operate at optimum cadence all the time: no gears to worry about, just small adjustments in the drive ratio. This would be an interesting development in a commuting context too: a bike where you don't have to make gear decisions, you just pedal and it works out the best ratio for you. The end of gears and gear changing altogether?

Dave is a founding father of road.cc, having previously worked on Cycling Plus and What Mountain Bike magazines back in the day. He also writes about e-bikes for our sister publication ebiketips. He's won three mountain bike bog snorkelling World Championships, and races at the back of the third cats.

Latest Comments

- JohnMcL7 6 min 21 sec ago

With the lack of any decent content updates for a long time now, the build up to the tenth anniversary and the big hike in monthly price we'd...

- Prosper0 26 min 2 sec ago

No offence to Endura, but same advice as to Rapha, I actually have all the kit I need, for probably several years. You need to go and win the next...

- froze 26 min 34 sec ago

Well, thanks for correcting me, I thought that bike was still in production! That bike was great though, too bad, so sad it's gone.

- bensynnock 2 hours 30 min ago

Here's one I got an AI to write......

- kingleo 2 hours 35 min ago

Anti-cycling programs or articles always get a lot of attention or comments, so they are very good for media advertisers.

- Cycle Happy 4 hours 30 sec ago

This is a screenshot in low light and drizzle at approx 15mph. It's pretty decent in my opinion. I have mounted mine on my offside seat stay within...

- chrisonabike 4 hours 20 min ago

Ah - yes, they've got an American Star the wrong way round (means the child carrier needs rearranged though). Or it could be a Facile but inverted?

- lesterama 6 hours 13 min ago

What a bunch of ases

- quiff 7 hours 6 min ago

It was only your comment in the carousel that first brought me here, and yet I still managed to read most of the page before remembering this isn't...

Add new comment

6 comments

talking of segways, is this taking branding too far?

DSCF6489.JPG

I have *got* to get me one of those

Take a look at the "developer kit" that NuVinci sells...it is almost exactly as you state for electronic shift control of the transmission. Instead of cadence, it senses vehicle speed to determine the correct speed ratio of the transmission.

You can create and upload constant cadence shift maps that keep the rider at an optimized cadence with infinitely smooth shifting.

http://www.fallbrooktech.com/09_LEV_Kit.asp

ah...still i spose it could be used with an electric job. will you be getting one in to test? maybe you copuld pair it up with a 'segway', a true frankenstein of a machine!

segway you mean? they may look a bit gash but they're properly good fun, a mate of mine has got one at his work.

i wasn't talking about electric bikes, just electronic control of gears. because it's not an indexed system it would be super simple to put the ratio changing in the hands of a computer: all you'd need it to do is measure your cadence and adjust the drive ratio accordingly. so when you stopped at a junction your cadence would drop to zero and the bike would automatically move to a low ratio to make it easy to get away from the lights. Then as you speed up and your cadence increases, the ratio is adjusted to keep your legs working at the optimum speed.

hmmm..as i was reading this, esp. the later bit about electric bikes 'sinclair C5' came to mind and that other thing that i forget the name off that you stood on and rocked and it moved or some such.