- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

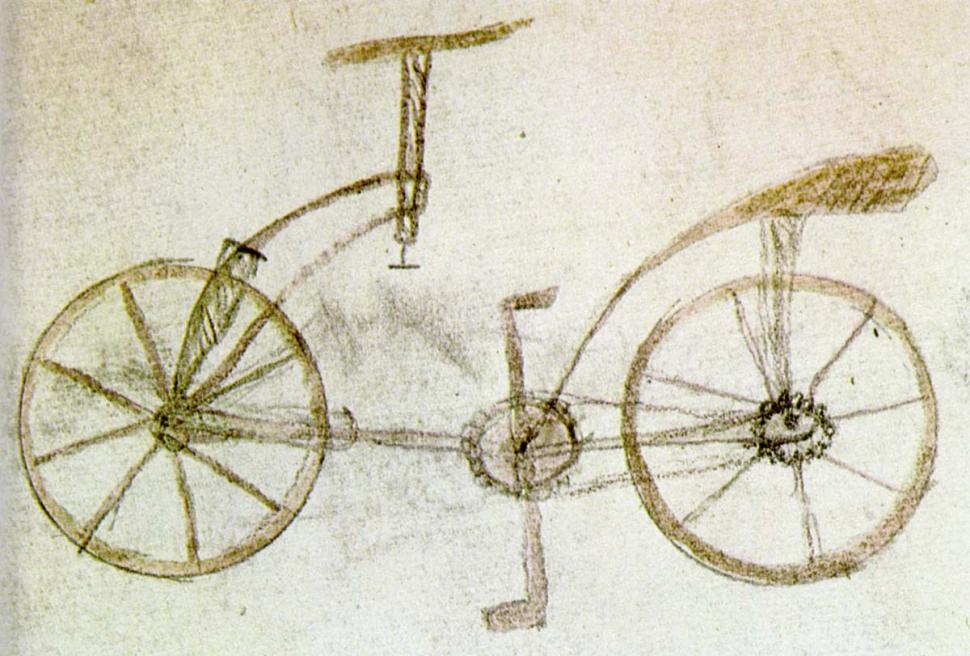

The bicycle sketch allegedly drawn by a student of Leonardo Da Vinci (Wikimedia Commons).jpg

The bicycle sketch allegedly drawn by a student of Leonardo Da Vinci (Wikimedia Commons).jpg7 cycling myths: Find out why frames don't go dead, Leonardo didn't invent bikes, & more

There are things every cyclist seems to believe, pieces of cycling lore passed down from rider to rider through the ages like holy writ. Problem is, an awful lot of them are either completely wrong, or based on a grain of truth that’s been mangled beyond recognition. Let’s pick a few of them apart.

Aluminium frames only last five years

Or two years, or whatever. There’s a grain of fact in this one and it’s all about metal fatigue. If a piece of metal is repeatedly flexed it will eventually break, as anyone who has idly bent and unbent a paperclip knows. This happens even if you don’t flex the metal enough to permanently bend it.

This is metal fatigue, and it’s an odd phenomenon because not all metals behave the same way. If you repeatedly flex a piece of steel by a large amount, it will eventually break. But if you only flex it slightly, it won’t. The load below which a piece of steel doesn’t break from metal fatigue is called the fatigue limit.

This kind of cyclical loading and unloading is exactly what happens to bike frames, so you can design a steel frame that will essentially last forever, as long as it’s not crashed and it’s protected from corrosion. (Bike designer Brant Richards has pointed out it's not quite that simple. "To actually hit true fatigue limit stress levels frame would be very heavy indeed," he says. Nevertheless, the relationship between stress and lifespan for steel is such that you can build frames that last literally decades.)

Aluminium is different. If you repeatedly load and unload a piece of aluminium it will eventually break, however small the load. However, the smaller the load, the longer this takes.

Having more material spreads the load around, increasing lifespan, and the shape of the piece makes a difference too. That’s why aluminium frames have fat tubes, because a larger and therefore stiffer tube has a longer fatigue life.

Using these design techniques it’s possible to make an aluminium frame that will last many years, which is why there are still plenty around from the 1990s.

To pick up a point made in the comments: yes, the particular alloy used matters. However, all aluminium alloys behave this way. Achieving a practical fatigue life depends on the design of the piece and the particular alloy used, which is why, for example, very light stems tend to be made of 7075 aluminium and 6061 is used in cheaper, heavier ones but both will be designed so as to reduce the kind of sharp edges where stress increases and reduces component life.

Steel frames go ‘dead’

You don’t hear this one as much as you did when steel was the dominant frame material. It was rubbish then and it’s rubbish now. As discussed above, a properly-designed steel frame can last forever, and that’s been obvious for decades.

How did this one get started then? A cynic might say that it’s good for bike shops to have people believe that you need to replace something you don’t, but I think there’s more to it than that.

On a new bike, everything works perfectly, and there’s a certain excitement about getting used to the differences in feel between your new and old rides. Your old bike, whatever it’s made from, feels familiar. Familiarity can easily become boredom. It’s not that an old bike feels ‘dead’ (whatever that even means) but that the unfamiliarity of a new one is exciting.

There’s one saddle height rule that works for everyone

Read half a dozen general books on cycling and you will find as many recommendations for ways to set the distance between your saddle and pedals. Saddle height nostrums will be based on your inside leg multiplied by a certain number (1.09 from pedal to saddle is common; 0.883 from bottom bracket to saddle is a suspiciously precise other); the angle of your knee; or placing your heel on the pedal with your leg straight, among others.

These methods produce a wide variety of saddle heights for any particular rider, which should ring alarm bells. Not only that, but they variously fail to take into account flexibility, shoe size and the sole-axle distance of your shoes and pedals.

At the very best these methods give you a starting point for where your saddle should be, though they can be off by quite a bit, especially the “inside leg times 1.09” rule, which tends to produce high saddle positions.

A bike fit expert will be able to help you fine tune things, though you can do this by feel as well, making small adjustments to saddle height. It’s hard to know what’s perfect, but aches and pains in hips. knees and ankles will soon tell you if something’s wrong. Carry an Allen key and make adjustments on the road, especially if you’re doing a long ride. 100Km of hills on a wrongly-adjusted bike can do damage that takes weeks to heal.

Road bike tyres must have a tread pattern for grip

This one’s simple. Car and motorcycle tyres have grooves in the tread to disperse water, otherwise they can aquaplane. Bicycle tyres, being much narrower, can’t aquaplane at typical bike speeds. In fact, you’d have to be doing over 200mph aquaplane a bike tyre, in which case Dave Brailsford probably wants to hear from you.

But tyre company marketing departments remain wedded to grooves, even though they can actually degrade tyre performance. That’s because the sections of rubber between the grooves can flex and squirm into them, and that increases the tyre’s rolling resistance.

Commenters to previous versions of this article pointed out that there's a theory that having lots of tiny edges in a tyre tread, as in a file pattern or herringbone, gives the tyre more points to key into the road surface. Maybe. But you're looking at a massive difference in hardness between tyre tread rubber and the mineral aggregates in a road surface. The tread is going to deform round the points in all those tiny bits of rock anyway, and having a few extra edges in the tyre tread seems unlikely to make much difference.

And tyres don't just mechanically key into road surfaces. The rubber also sticks to the road by a process of molecular adhesion involving Van der Waals forces between the rubber and components of the road surface. If there's a void in the rubber, those forces can't happen, so a smooth surface provides better grip.

It’s telling that when a tyre manufacturer wants to make a tyre for those situations where every second counts, such as a time trial, they make slicks. Look at the Continental Grand Prix Supersonic, for example, or, for a slightly less extreme example, Michelin’s Power Competition tyres.

But why, you ask, do some very high-performance tyres like Continental GP5000s still have grooves? The answer seems to be aerodynamics, the tiny grooves helping prevent turbulent, draggy air flow over the tyre. The folks at AeroCoach tested Conti's almost-slick GP TT tyres against GP5000s and GP4000s and found that the overall resistance of the GP TT was nevertheless slightly better.

Carbon frames go ‘soft’

Sound familiar? It’s the modern version of ‘steel frames go dead’ and ‘aluminium frames only last five years’. And it’s almost as daft.

As long as it’s not crashed, a carbon fibre frame won’t become weaker in use. In fact, many carbon fibre frames hugely exceed standard tests for fatigue life, to the point where manufacturers get bored and turn off the testing machines.

It doesn’t seem like they get more flexible either, at least not in ways riders can tell. The first widely-available carbon frames appeared in the early 1990s, and some have been in continual use ever since. They’d be seriously floppy by now if this was a real issue.

However, while the fibres themselves are almost infinitely durable, you can imagine that the resin might degrade over time with repeated flexing. It turns out this is what happens.

Tour magazine flex-tested carbon fibre forks and found that after 100,000 cycles they became less stiff. Chuck Texiera, a senior engineer at Specialized told CyclingTips.com what happens: “The epoxy matrix will at some point start to form little cracks, and then over time it will just have the connectivity of the fibre.”

As with so many of these beliefs, there’s a disconnect between what the engineering says is happening and what a rider can actually feel. A frame might be less stiff, but Texiera doesn’t think a rider could tell.

He said: “Over really extended periods of time, you can expect the stiffness of the frame to change ever so slightly but it’s such a small number. We can measure it but I really wouldn’t think it would be perceivable.”

Rotating weight is crucial

“An ounce off the wheels is worth a pound off the frame,” goes the old saying, implying that rotating weight, especially on the wheels, is supremely important. The claim is sometimes laid out in less hyperbolic terms that weight on the wheels counts twice because when you accelerate you have to get it both spinning and moving forward.

Problem is, it’s not true. In 2001 bike engineer Kraig Willett analysed the forces on wheels and concluded:

“When evaluating wheel performance, wheel aerodynamics are the most important, distantly followed by wheel mass. Wheel inertia effects in all cases are so small that they are arguably insignificant.”

The idea that rotating mass is important comes from the belief that wheel inertia matters, because it’s inertia that has to be overcome to accelerate a wheel. But Willett clearly demonstrates that wheel inertia doesn’t matter, so rotating weight is also relatively unimportant.

Why not? Well, you don't do much accelerating when you ride a bike, and even when you do the acceleration is relatively low, so the power expended accelerating a bike with ‘heavy’ wheels is only fractionally higher than that needed for light wheels. Overall weight matters when you’re climbing, but even that’s not as big a factor as people imagine and it’s a lot cheaper to save weight off your middle than the bike.

In fact you spend most of your time, and therefore effort, shoving the air out of the way, and that’s a far better basis for choosing wheels. The roughly tenfold difference in the effect of aerodynamics versus total mass means you’re far better off with a pair of good aero wheels than a pair of light ones.

Kirkpatrick Macmillan or Leonardo Davinci invented the bike

It’d be nice to believe the bike was invented by a Scottish blacksmith, but the evidence is very thin indeed.

The claim that Kirkpatrick Macmillan built a treadle-powered two-wheeler in 1839 didn’t emerge until after his death in 1878. A relative of Macmillan, James Johnston, made the claim in the 1890s, but was unable to produce any documentary evidence that what Macmillan had built was a two-wheeler.

The story goes that Macmillan built the first bike, but over the following years others copied the design. Cooper Gavin Dalzell was supposed to have built one in 1845, but again there is no contemporary evidence.

Treadle-drive tricycles and quadricycles were not unusual in the middle of the 19th century and it seems likely that the late-19th century recollections of velocipedes that formed the basis for Johnston’s claims were actually of three-or four-wheeled vehicles. Cycling historian David Herlihy covers the Macmillan claims extensively in his book Bicycle: The History and points out that none of the claimed accounts of Macmillan’s bike or others derived from it actually say it was a two-wheeler.

This, Herlihy points out, is remarkable, given what a novelty a two-wheeler would have been. When the French front-drive bicycles emerged in the late 1860s they were a sensation, because riders were able to travel on them without touching the ground. That Scottish newspapers of the time made no mention of this is remarkable.

“After all,” Herlihy writes, “a single French-style bicycle in the United States in 1866 led to both a clear-cut description of the article in a local newspaper and a patent application. It seems highly improbable that an arbitrary number of equally eye-catching machines could have operated in and around Scotland's largest cities—or anywhere else for that matter—for nearly thirty years without leaving the slightest paper trail.”

Herlihy doesn’t even bother to mention Leonardo da Vinci’s alleged invention of the bike. A sketch of a bicycle-like device emerged in 1974, claimed to be part of Leonardo da Vinci’s Codex Atlanticus. The sketch was attributed to Gian Giacomo Caprotti, a pupil of da Vinci, and was claimed to be a reproduction of a lost drawing of a bicycle by da Vinci himself. It was later established to be a forgery, though da Vinci’s reputation and that of literary historian Augusto Marinoni were powerful enough that it took until 1997 for the forgery to be unveiled.

According to a 1997 paper by Prof. Dr. Hans-Erhard Lessing, the Codex Atlanticus was examined by another da Vinci scholar in 1961 and the bicycle sketch was not present, though there were some geometrical doodles that the forger incorporated into the bicycle.

Lessing writes: “the bicycle sketch is definitely a recent forgery that can be dated between 1967 and 1974”.

But why would anyone forge a drawing of a bike? The short answer seems to be ‘national pride’. The bicycle was a seminal device that laid the basis for many vital technologies of the 20th century. Karl Benz’ Patent Motorwagen — the first internal combustion engined vehicle — was essentially a tricycle with an engine, with roller chains for power transmission, tension-spoked wire wheels and a tubular steel frame. The Wright brothers, who flew the first heavier-than-air plane in 1903, were bike mechanics and like Benz used bike technologies to save weight on their Flyer.

There’s a certain kudos, then, to being the country that invented the bicycle, which is why the strongest proponents of the Da Vinci drawing were Italian, Macmillan advocates were Scottish and so on. Marinoni never conceded the Da Vinci sketch was a forgery and as recently as 2009 his followers were still defending it, albeit rather incoherently.

John has been writing about bikes and cycling for over 30 years since discovering that people were mug enough to pay him for it rather than expecting him to do an honest day's work.

He was heavily involved in the mountain bike boom of the late 1980s as a racer, team manager and race promoter, and that led to writing for Mountain Biking UK magazine shortly after its inception. He got the gig by phoning up the editor and telling him the magazine was rubbish and he could do better. Rather than telling him to get lost, MBUK editor Tym Manley called John’s bluff and the rest is history.

Since then he has worked on MTB Pro magazine and was editor of Maximum Mountain Bike and Australian Mountain Bike magazines, before switching to the web in 2000 to work for CyclingNews.com. Along with road.cc founder Tony Farrelly, John was on the launch team for BikeRadar.com and subsequently became editor in chief of Future Publishing’s group of cycling magazines and websites, including Cycling Plus, MBUK, What Mountain Bike and Procycling.

John has also written for Cyclist magazine, edited the BikeMagic website and was founding editor of TotalWomensCycling.com before handing over to someone far more representative of the site's main audience.

He joined road.cc in 2013. He lives in Cambridge where the lack of hills is more than made up for by the headwinds.

Latest Comments

- ErnieC 1 hour 1 min ago

or Team Bahrain ... selective outrage.

- newbankgyratory 2 hours 3 min ago

This website offers suitable data: https://www.automobiledimension.com/large-suv-4x4-cars.php

- newbankgyratory 2 hours 36 min ago

Perhaps park the goods in a US Customs Bonded warehouse and then import them out of there when the tariff nonsense settles down?...

- Dnnnnnn 32 min 23 sec ago

Good to see a road.cc review of what must be one of the UK's best-selling 'proper' road bikes....

- PRSboy 3 hours 31 min ago

Another thing ruined by the Americans

- Miller 4 hours 50 min ago

Nice to see WvA featuring in the finale.

- Miller 4 hours 53 min ago

I have known more than one elder statesman of the club die of a heart failure while out on a ride. Sometimes I feel that's about to happen to me,...

- Pub bike 5 hours 10 min ago

Via the "wireless active steering system".

- Hirsute 5 hours 34 min ago

137m is the farthest I have observed when quickly looking at the Garmin unit....

- pockstone 5 hours 51 min ago

Yours worked wonders, but if you insist, I'll hop to it...why the need for extra police? Did the fire brigade bottle it?

Add new comment

2 comments

Great article. Informative and entertaining.

I've always loved the story about Leonardo da Vinci sketching out a bicycle. Robert Penn's superb "It's all about the Bike" has a whimsical account of how this occurred and is well worth reading.

OK, must admit to being guilty of never really thinking about this and just assuming that more tread = better grip. Clearly, it's obvious that a bike can't reach sufficient speed to aquaplane, but doesn't a tread help braking in the wet? I assumed (again, without really thinking about it) that by providing a channel for the water to disperse the tread allowed the non-treaded part of the tyre to get a better grip, is this not so?