- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2021 New Motion Labs Enduo Evolve

2021 New Motion Labs Enduo EvolveNew Motion Labs reinvents sprocket for increased efficiency

UK based startup New Motion Labs has revealed its new sprocket design, the Enduo Evolve, for increased drivetrain efficiency, longer lifetime and less friction.

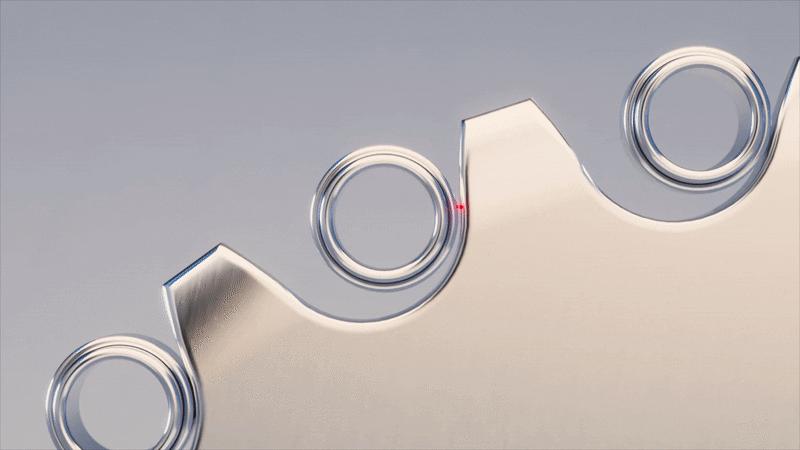

The new sprocket design is said to enable a conventional roller-chain to transfer power on both sides of the sprocket tooth by 'Dual Engagement' and contains half the number of teeth of a normal sprocket to do so. Up to 30% increase in drive lifetime and up to 1% higher efficiency are promised by New Motion Labs.

“By enabling the roller-chain to securely engage on both sides of the sprocket tooth, instead of pushing the tooth on one side like conventional sprockets, movement between the tooth and roller is eliminated,” says New Motion Labs.

“This drastically reduces the frictional losses over and above conventional drivetrains, increasing the overall efficiency and lifetime of the chain, chainrings, and sprockets.”

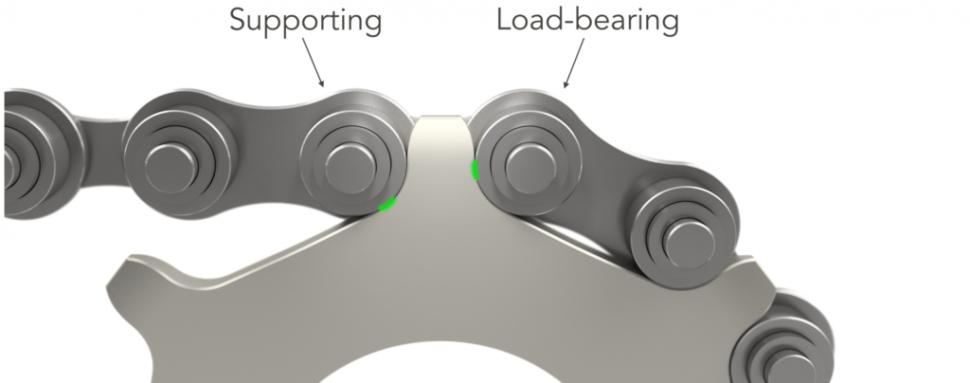

In the Enduo Evolve system, each roller is said to perform a different function on the tooth: “One roller is load-bearing, meaning that its primary role is to transmit load between the sprocket and the chain.”

The roller on the other side is only a supporting roller. This is unlike conventional chainring/sprockets where every roller is load-bearing.

“While this [supporting] roller does not apply torque directly to the sprocket/chainring, it supports the load-bearing roller on the tooth and prevents roller movement and any losses associated with such movement on the tooth,” says New Motion Labs.

For this Dual Engagement, Evolve sprockets and chainrings have half the number of teeth of corresponding conventional sprockets while maintaining an equal number of points of articulation.

This reduction in the number of teeth for the same sized sprocket or chainring is said to have very little effect on its strength.

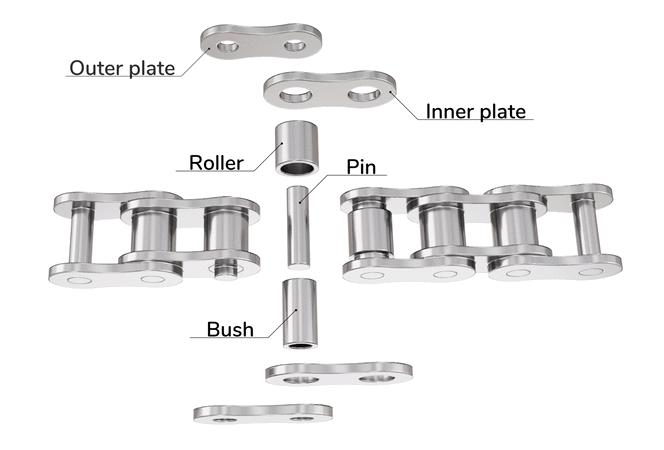

With its alternating roller types, New Motion Labs says the system enables higher efficiency drivetrains by significantly mitigating the detrimental friction effects of critical bush articulations.

New Motion Labs explains: “By ensuring that the supporting roller always articulates via a bush articulation, the effect of the inefficient, but unavoidable, bush articulation is greatly reduced, increasing drivetrain efficiency overall.

“The teeth of the Evolve sprockets and chainrings can, in theory, engage either the outer or the inner links of a standard roller chain. However, to achieve the maximum efficiency, the Evolve sprocket teeth should always engage the outer (wider) links of the roller chain.”

Maintained efficiency is also promised throughout its lifetime. Roller chains typically elongate over time due to wear. According to New Motion Labs, “a certain amount of elongation is allowable, typically up to 0.75%. Nevertheless, chain stretch has a deleterious effect on the efficiency of the conventional roller-chain drives.”

New Motion Lab claims that with the Enduo Evolve, “the effect of chain elongation does not have such a negative impact on the drivetrain efficiency” because of the nature of the alternative roller types (load-bearing and supporting) that adopt different positions as the chain elongates. Thanks to this higher performance is promised for longer periods.

New Motion Labs full explainer video can be found here:

New Motion Labs is an IP licensing company and so will not be manufacturing and selling the product themselves. "We license the technology to manufacturers, who are then able to produce and sell the physical products to the end user."

When will it be available? "We are nearing the end of testing and expect the product to be ready Q2 2021 for track cycling and Q3/Q4 2021 for road cycling and e-bikes," says New Motion Labs.

Latest Comments

- EK Spinner 11 min 59 sec ago

I have said before that a driving ban needs to be treated like a suspended sentence, breaching that ban should automatically result in jail time...

- chrisonabike 20 min 15 sec ago

It may have been a long time ago in a galaxy far, far away, but that doesn't change logic. Or are you saying the Dark Side is seriously...

- chrisonabike 29 min 2 sec ago

I've had to put my wellies and gloves back on again ... but perhaps a thoughtful consideration of the following would be helpful for those - with a...

- john_smith 40 min 26 sec ago

If you'd read it a bit more carefully you'll see that it also requires each new home to have at least three parking spaces. So it shouldn't be a...

- FionaJJ 1 hour 3 min ago

It took me ages to make sense of the story, because the bit about having bike parking is irrelevant to the issue about access. ...

- chrisonabike 1 hour 43 min ago

But how on earth do you expect people to know that's not allowed?...

- David9694 2 hours 11 min ago

Man flees after crashing into grade II listed Dorset home https://www.bournemouthecho.co.uk/news/24263845.man-flees-crashing-grade...

- wycombewheeler 2 hours 24 min ago

If plod can't get through their in their cars, then criminals will use it to evade them because heaven forbid the police should patrol on foot or...

- chrisonabike 2 hours 28 min ago

The questions would be "who / what do the rules serve? What are we willing to pay / accept to maintain or enforce them?"...

Add new comment

20 comments

It all went downhill from here!

In marketing terms this direct drive system, by eliminating the drive train, reduces associated power losses to zero, saves 100% of the associated weight, is maintenance free. Plus, with no need for expensive lubricants and cleaning, offers the cost conscious cyclist ongoing monetary savings for a lifetime ownership.

Interesting concept but will it work? As with any new product the suckers will line up like crazy to buy it, so I'll let them line up first, wait a couple of years and see how things are going before I would ever decide to buy it. I can also see some company announcing that they created a special lube to work only for that technology and try to sell a 4 ounce bottle for $40, when in reality it's just oil.

this will not keep the engineers at shimano and sram awake at night. half the number of engagement points give half service life. simple as that. on small cogs it will be disastrous.

just forget it.

How did you work out it is half life? They claim 30% increase in life.

How did you work out it is half life? They claim 30% increase in life.

I think he just ignored all their technical claims and decided it was just a cog with half the number of teeth. It's easy to be sceptical because many 'new developments' are just bollocks and never appear on the market. But not all of them!

PS The New Motion documentation also illustrates radical new technology with drivetrain on the left, and discs on the right of the hub.

It's even more interesting than it appeared at first. You 'tune' your chain/sprocket combination for either efficiency or durability by moving the chain one link with respect to the Enduo sprocket teeth- the tooth engages either between the outer link plates (efficiency) or between the inner plates (durability). It appears they envisage Enduo chainrings as well, so it's going to be a bit of a faff getting both chainring and sprocket 'tuned' for the same thing. Unfortunately, they're competing with Big-S's new durability focussed Linkglide systems, so S isn't going to be manufacturing Enduo.

In any case, good luck to them. I have patriotically downloaded the booklet on the website.

Curious about the effects of this on changing gear. On all the diagrams, it looks like the sprocket teeth only fit within outer-plates, not inner plates. I suppose a bit like the "thick" teeth of thick-thin sprockets. So that then means if changing gear, if the chain doesn't engage immediately with the right sprocket (i.e. a sprocket tooth makes a bee-line for an inner-plate) then the chain's going to lurch forwards twice as far as with a conventional sprocket before it settles down. So I do wonder whether this is going to make the experience rather "lurch-y".

On all the diagrams, it looks like the sprocket teeth only fit within outer-plates, not inner plates

No, the article states:

teeth of the Evolve sprockets and chainrings can, in theory, engage either the outer or the inner links of a standard roller chain. However, to achieve the maximum efficiency, the Evolve sprocket teeth should always engage the outer (wider) links of the roller chain

In order to sustain that highest efficiency you'll have to have an even number of links in the chain, and the equivalent of even numbered teeth on your new Evolve cassette. Having only even number equivalent sprockets is no hardship to most of us, but is this 1% worth it in comparison to the effects of wind resistance, different chain lubricants etc.?

I'm much more intersted in doubling the life of the chain and sprockets.

Plus, think of the weight savings from all the missing teeth! It's nearly a 50% savings in total sprocket tooth weight!

I'm much more interested in doubling the life of the chain and sprockets

Agreed. There was a recent claim that Shimano's proposed Link-Glide sprockets would last longer?

i bet all the lube manufacturers are getting

wetexcited about the possibility of dedicated product offerings for this New TechI don't pay much attention to 'up to x%' figures, but if 1% was achieved on bikes used by people in real life, it would be significant unless drivechain losses are such a small fraction of achieved power that the gain is insignificant. Anybody know offhand how much of the effort of the average punter goes into drivechain losses as opposed to wind resistance?

Drivetrain losses are a few percent of power. Maybe approaching 10% for small sprockets at high cadence. There's some relevant data here.

https://www.cyclingabout.com/drivetrain-efficiency-difference-speed-betw...

"Up to 1%"

Sold !!

How do I measure the gearing though ?

This is just them being honest. Probably because they're trying to sell their idea to other engineers, who are fantastic bullsh!t spotters, unlike many cyclists.

If they were a cycling drivetrain company, they'd have data showing efficiency going from 97% to 98%, and claim "up to 33% efficiency improvement!"

The increase in lifespan is attractive though.

But going back to my question, how do you measure the gearing and what will the gaps be between gears? Seems equivalent to 10/12/14/16/18 spacing?

Same as before, assuming the chain ring is also missing every second tooth. If not, just double the tooth count on the gap-toothed sprockets.

Of course you can't have odd-toothed equivalent sprockets, so that might mess up the jumps between gears.

No. Like it says, torque is applied on one side only. The other side; no torque, no power. It gives "stability" only, whatever that means, but obviously it isn't pulling the tooth behind.