- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

ceramicspeed aero2

ceramicspeed aero2CeramicSpeed tests radical drive shaft concept in Specialized wind tunnel leading to claims it’s more aero than a standard groupset

Remember the CeramicSpeed Driven drive shaft concept that was unveiled at the Eurobike show last year? The Danish bearing specialist has been beavering away at its concept which does away with chain and derailleurs and is claimed to be 99% efficient and recently got together with Specialized to aero test it where it proved to be more aero than a conventional groupset.

The aero test involved fitting the prototype pinion drive shaft, which uses 21 CeramicSpeed bearings, to a current Specialized S-Works Venge aero road bike and testing in Specialized’s very own wind tunnel, dubbed, Win Tunnel.

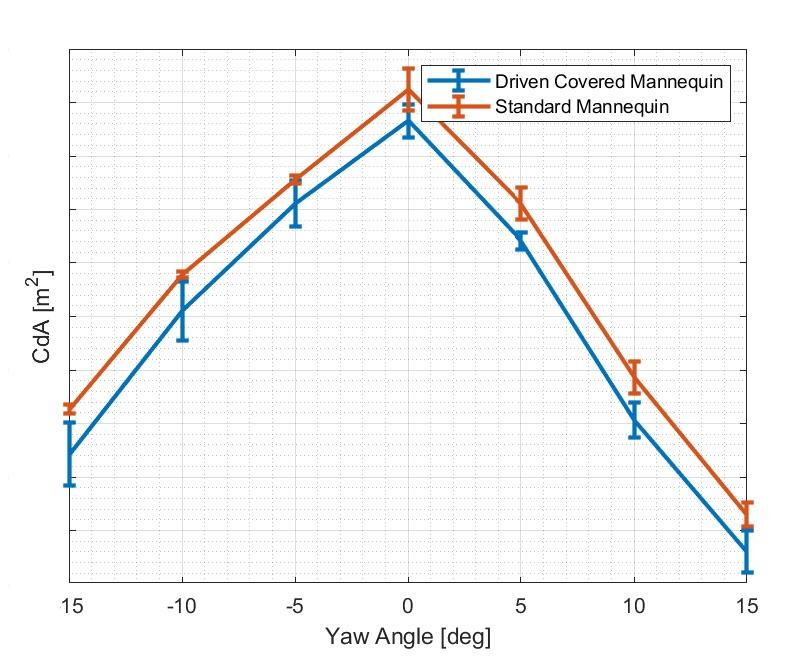

Apparently, after hours of testing, this setup was shown to produce 3% less drag than a standard Venge across all tested yaw angles. Or in other words, as much as an 8-second improvement over 40km, though neither company states the speed the tests were conducted at for full clarity.

The improvement in aero performance is said to be the equivalent of the aero gains Specialized has engineered in its latest Venge compared to the previous Venge ViAS. “The results we measured are comparable to the aerodynamic improvement of the Venge ViAS to the current generation Venge. On a flat course, the aerodynamic gains made are in the same order of magnitude as the gains through the reduced drivetrain friction,” explains Ingmar Jungnickel, Aerodynamics R&D Lead at Specialized.

This was the one test, but Specialized reckon there is more potential in the CeramicSpeed Driven. “Considering that was the first attempt, it seems that the system has the potential of further aerodynamic gains in the future,” added Ingmar Jungnickel.

If you missed the story around the unveiling of the CeramicSpeed Driven drive shaft at Eurobike last year, and 1.6 million of you have watched our YouTube video with nearly 1,500 comments, it is the result of the bearing specialist wanting to explore the possibility of a completely efficient drivetrain. For reference, a regular drivetrain is in the region of 90-98% efficient, depending on the conditions of the drivetrain.

How is it so efficient? It’s all about reducing the points of contact. A regular drivetrain has eight points of sliding friction, Driven eliminates them all by using a pinion-style drive shaft system and employing 21 CeramicSpeed bearings that provide low rolling friction and good durability.

“CeramicSpeed has proudly accomplished what many have said couldn’t be done. We achieved a 99% efficient multi-speed drivetrain while eliminating the chain and complex rear derailleur. Advancements in drivetrain technology have been evolutionary since the 1920s. Driven is truly revolutionary given its unique rolling element power transfer and unmatched efficiency. The Driven concept has the ability to change the way the cycling industry views drivetrain design and drivetrain efficiency,” explained Jason Smith, Chief Technology Officer and founder of Friction Facts, who is based out of Boulder in the US and has headed up this project.

Drive shafts and chainless bicycles are nothing new in cycling. A quick Google search will provide plenty of evidence of bike companies using chainless drivetrains, mainly for urban and city bikes, and alternative drivetrains have been around since the invention of the bicycle. But the modern derailleur-based drivetrain has been refined and improved over the years and has become the de facto choice for most bikes, from racing bicycles to hire bikes.

'Since we launched Driven at Eurobike last year, rideability and shiftability has been our primary R&D focus and we have made incredible advancements in only 10 months. We’ve surpassed a speed of 45 km/h during rider load testing at the velodrome, and have had major breakthroughs in a shifting mechanism that we’re excited to unveil in due course. We’re now looking forward to showcasing how Driven and the developments we’ve made can truly shift the future of bicycle drivetrains,” said Martin Banke, head of Cycling division at CeramicSpeed.

It can’t be overstated that it’s still very much a concept, or an early prototype, at this stage. We’ve not seen it in action though the company has got a working prototype and tested it in the velodrome, there’s a really big question over changing gears. How the shifting mechanism performs is something we’re all keen to see, and it’s still being developed. In a post on social media, the company said “we’ve not stopped on the shifting pursuit. Keep a close eye on upcoming developments.”

So more than just an elaborate concept to grab a few headlines at Eurobike last year, the company is determined to keep developing it with the aim we presume of presenting a full working prototype that hopefully we’ll get to ride one day. It could well be the future of cycling as the company hopes but it’s got an extremely long way to get before realising that dream, but we’re excited to see a company boldly trying something different.

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- Hirsute 1 hour 23 min ago

Radar tells me their closing speed, if they are slowing and how far away. Then I decide to say a prayer. The change of light pattern is incidental.

- lonpfrb 1 hour 43 min ago

Quite so, which is why our village 20mph zone covers the whole residential extent. Of course, enforcement is another thing..

- lonpfrb 2 hours 9 min ago

No, that's very doubtful while proper testing would be fully destructive.

- TheBillder 2 hours 55 min ago

In that £1000 exactly scenario, beginners should probably be made aware that pedals will be extra.

- don simon fbpe 3 hours 23 min ago

What's wrong with dropping down on to the Millenium Bridge, or the swing bridge, then the brief, but satisfying climb back up the hill? #training....

- chrisonabike 4 hours 4 min ago

The relatives might of course disagree, but in general I'd countenance a relatively light sentence* if only we could fix it so that those who...

- ktache 4 hours 43 min ago

Id forgotten that I got a second hand set of project two's for my getting to work bike over twenty years back.

- Veganpotter 5 hours 40 min ago

My bet is that all these tires popping off are from people with bad pressure gauges or they're simply just putting too much air in on purpose. ...

- chrisonabike 6 hours 56 min ago

David9694 - you were right! These new autonomous vehicles really are conspiring to run out of control!...

Add new comment

25 comments

The drive train on a penny farthing is 100% efficient only inasmuch as it doesn't exist.

There are geared unicycles (with an internally geared hub) and chain driven unicycles (allowing the rider to sit higher without having an elephantine wheel) so a Ceramic Speed unicycle should theoretically be possible. If it worked on two wheels.

Imagine how fast a Ceramic Speed unicycle would be

That would be nuts

41A51uamF3L._SX331_BO1,204,203,200_.jpg

Ewe will get over it

Kawasaki used to make (perhaps still do? I'm out of touch) some shaft drive models. They had the GT550 and 750, essentially shaft-driven, detuned, "touring" versions of the GPz, and going further back a shaft-drive version of the Z900 (I think).

Shaft-drive bikes, Columbia brand I think, were used in the PotUSA's "cavalcade" aroudnd 1900. Imagine that now! If only!

Readybike, the bicycle hire scheme in Reading had drive shaft bicycles. I doubt if they worried about efficiency much. Driven a 3 speed internal hub. One day they just all disapeared.

Mobike hire bikes in Manchester were the same, both in terms of shaft drive and sudden disappearance.

I rode one once - truly a once in a lifetime experience. The teeth jumping on the shft drive was the least of it.

I used to have a shaft-drive motorcyle: a CX500. It made removing and refitting the rear wheel much easier and cleaner (okay, less filthy) than with a chain. Can't comment on efficiency, don't recall torque steer being a problem, but the shafts do wear and unlike a chain you can't see it till it's too late (it didn't start slipping or skipping, it would work perfectly normally until one instant it suddenly lost all drive; I had this happen on two separate bikes, same model, and to friends with CXs).

As for a peak of 1500W, I can only wish!

I knew someone who had a CX500, and since it wa the only bike I'd ever seen with a driveshaft I thought it was pretty cool. I do see the advantages of shaft drive bikes, but I always felt the cost of replacement of the driveshaft outweighed the low maintenance aspect- parts were/are quite specific.

The torque steer part is something you'd run into as an issue on a more modern high end bike- something like an R6 upward. The power to weight ratio is so high, and the engine generates so much torque, the chassis would have to be beefed up significantly to deal with it, especially around the rear subframe. This adds weight, and when added to the weight of the driveshaft it's quite significant.

Just think how efficient it would be if ceramic speed used NTN bearings instead of ceramic speed ones!

Great to see a ball bearing seller do what all those motorcycle manufacturers and their billions invested in R&D couldn’t, and come up with a shaft that’s more efficient than a chain. Perhaps that last 1% of efficiency can be found by rotating the rider and cranks by 90 degrees so that the legs can drive the shaft directly?

Sorry, but you blatantly don't know what you're talking about trying to draw a comparison here.

1) They're a long way from coming up with anything. They have a conceptual design, that's it. Hasn't been subject to any kind of real world testing- as far as I know they haven't even come up with a system that can change gears (yet). It remains to be seen whether this will progress to being a production bike or whether it will die at concept phase- it wouldn't be the first idea to be shown at Eurobike only to be never seen again.

2) Shaft-driven motorbikes do exist- there a quite a number of large touring bikes that use shaft drives. Their disadvantages are generally considered to outweigh their advantages, which is why they're not more popular. It remains to be seen whether the Ceramic Speed design will be any different (assuming it makes it past concept).

3) The problems facing a shaft-driven motorbike aren't about some relatively pointless marginal gain in efficiency- if you want to make a motor driven drive train more efficient you'd start at the engine and gearbox. Gettin 1% more out of the power transfer system is neither here nor there.

4) While in theory bicycles and motorcycles have some similarities in the problems they face, in reality it's a completely different playing field. Torque steer isn't something a bicycle has to contend with- it's one thing designing a system that can withstand a peak of maybe 1500W, it's another to design a frame for nearly 100 times that. Drive chains on motorbikes also don't have to deal with changing chain lines, which is most of CeramicSpeed's raison d'etre.

It might sound like I'm massively down on the CeramicSpeed concept...I'm actually not, I like innovation, even just for innovation's sake. However, I do think this will remain an ultra-high end design, and we won't see it trickling down into the affordable range any time soon, if at all.

Shaft-driven motorbikes exist, it's a shaft-driven motorbike that's more efficient than a chain that doesn't. Shaft-driven pedal bikes have existed for years and years too.

https://en.wikipedia.org/wiki/Shaft-driven_bicycle#History

On the other hand, you're right that there's no good reason why a motorcycle manufacturer should concentrate on trying to do that, and that this isn't yet close to a working system.

the claim in the article which you don’t appear to have read, is that a chain is between 90-98% efficient, and this shaft drive is 99% efficient, thtat what I am poking fun at.

I am well aware of shaft driven motorbikes, I am a motorbike as well as a cyclist. The extremely popular BMW GS like what Ewan McGregor rode around the world on, is a shaft drive. Great for that sort of riding, low maintenance, less chance of snapping etc. Shafts have been around for a long time so it’s well established that on the flip side of reliability that they aren’t as efficient as a chain.

Shaft drive bicycles have been around just as long, the chain was the improvement. Just like pneumatic tyres taking over from solid wheels, you’ll always see nonsense like this stunt trying to bring back some largely obsolete technology packaged as new and improved before it disappears for another few years

So basically what you're saying is...I completely missed the sarcasm in your post?

Now I feel sheepish.

Is a penny farthing bike 100% efficient?

Yes.

This drivetrain again? Cool hype piece to make CeramicSpeed look more innovative than they really are, but never going to work... There's not enough inherent rigidity in the system to keep it from skipping gears. The only way to shift is free-spinning under no load. Cannot be used in dirt/muddy environments.

I would have thought it made more sense to have the shifting at the front where everything is more rigid, but then you wouldn't be able to see it...

Sorry but unless you are involved with the design of this system or a similar one you can't make such sweeping statements about an in development product.

In terms of rigidity the shaft ends are seated pretty deep in the teeth so I don't see them slipping out easily. The distance between the axle and the contact point is also not particulary far.

In terms of working with muck, firstly as seen on the second prototype it can be enclosed more than a chain drive and secondly the gear teeth should shed dirt due to CF load, finally the roller bearings are not making snug contact in the teeth on the cogs they should just push dirt on to a non contacted surface.

I can also conceptually think of a number of ways to make this shift gears under load.

One would be that as roller bearing element moves down the shaft it changes phase slightly (moving on a spline) deloading it as the move is triggered. The same trick is them pulled in the oposite direction to allow the roller bearing element to match the next cog.

Shifting will be electrically actuated with timings more in line with a variable valve timing system on an ICE than anything on a bike.

So can I, but I can absolutely guarantee that it's getting a reliable and robust gear shift that's going to sink this concept: it's a much more complex engineering problem than anything demonstrated so far.

Agreed - amusing how negative some are towards this.

negative or realistic?