- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

Perfect fit: getting a bike made to measure

It’s all coming together. The Viner Maxima RS road bike that we’ll eventually be reviewing on road.cc, that is. The made-to-measure carbon frame has just been crafted in Italy and we’re getting pretty excited about slinging a leg over the finished bike.

If you visit road.cc regularly – and if you don’t, what the hell are you doing with your life? – you might remember that I was measured up for a super high-end Viner a few weeks back by bike fit specialists Velo Solutions. Read all about it here.

Briefly, for the late-comers at the back and the hard of remembering, Guiseppe adjusted the fit on my current bike in a short session at Le Beau Velo in Shoreditch, London – all perfectly painless, I can assure you. Once he was happy that everything was absolutely spot on, he measured it up and tapped all the details into the computer, and that was that for a few days.

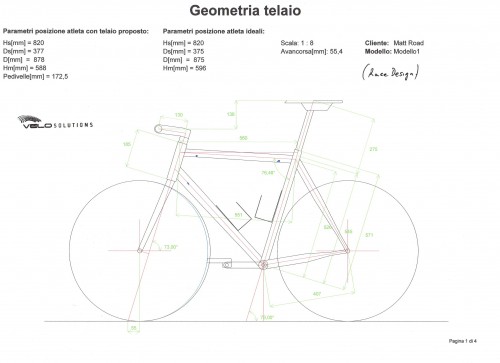

Then, ping! A couple of designs arrived in my inbox. Guiseppe had been away, done the calculations – probably scratched his head, whistled through his teeth, and spoke to himself in Italian, I’m guessing – and come up with two different designs based on the bike fit we’d done: a ‘sportif’ option, and a ‘race’ option.

Most of the key dimensions were identical. The distance between the bottom bracket and the top of the saddle, for example, was the same across the two designs, as was the overall reach to the bars. The main difference between them was that the top tube on the race design was a centimetre shorter than on the sportif design. This meant that the wheel base, the distance between the two hub axles, was a touch shorter too, which tends to make a bike more manoeuvrable.

In order to compensate for the shorter top tube and get the reach the same, the race design had a longer stem – which slows the steering and adds a bit of stability. There was a small difference in the head angle too and a tiny difference in the amount of trail. Trail, if you don’t know, is the distance from the middle of the front tyre/road contact point and the point where an extended line drawn straight through the centre of the head tube hits the ground.

Anyway, let’s cut to the chase: I opted for the race design, chose the stealthiest finish known to man, and fired my email back to Velo Solutions in double-quick time. They sent the chosen design over to Viner who cracked on with the manufacturing process...

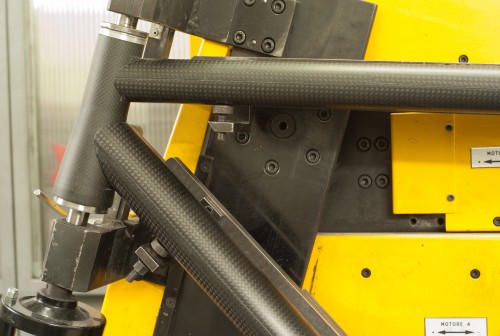

Believe it or not, the carbon tubes that Viner use for the Maxima are produced to the specific requirements of each customer. In other words, there’s no stock pre-manufactured tubeset. The tubes are made to suit the size, weight or potential power of each rider. Crikey! When they say they tailor these frames, they really mean it.

The frame builder cuts the tubes to the correct length, mitring them to the specific angles required, and then puts them onto the jig – called the ‘mask’ – which has been set up for the size and geometry of the frame. The mask is actually a technical bit of kit. Digitally controlled, it ensures that everything is made to within 0.1mm/0.1° of the design spec. It’s a high-tech business.

The next step is to bond the frame tubes together with an epoxy resin that Viner have developed. This just keeps the tubes in place so the frame can be removed from the mask for the proper jointing to be done. Once the resin is on, the frame is part cured in the autoclave – a high pressure oven, essentially – to set correctly, and then it can be taken off the mask. At this stage it’s already looking a lot like a bike frame.

A bit like Look and Learn, this. Okay, so the tubes are in place. Next up, it’s time to make the compression joints – the permanent joints that have to hold the tubes in place when you’re hurtling downhill at 50mph. You want this done right, and Viner employ specialist staff for the job… which is reassuring.

These wrappers first cut individual sections of pre-preg carbon fibre (carbon fibre cloth that has already been impregnated with resin) to the correct shape, then build the lugs making sure there’s no contamination between the different layers. Guess how many pieces of carbon they use: up to 150 on one frame.

Once they’re done, the compression joints are wrapped in compression tape and the internal sections of the frame are filled with a silica sand to stop them getting crushed when the frame is put back into the autoclave. The frame then goes into a vacuum sac ready for curing.

Viner have developed their own curing process and the details are secret. It’s all very hush-hush, the old frame building game. What we do know is that they put the frame into the autoclave that uses a balance of internal and external atmospheric pressure and temperature curves to mould the individual layers of carbon into solid sections of carbon and resin. The new joint is highly compressed with ultra low voids, which means there’s an even mixture of resin and carbon with no micro air bubbles in there.

Then they take the frame out of the autoclave, let it cool, and it’s ready to be hand finished. The compression joints can be made to be smooth and invisible or the frame can be left with a visible lug appearance. They check the frame is still in perfect alignment and track, fit any accessories that have been requested, and it’s sent off to be painted.

And that’s where we’re at. Our Viner Maxima RS frame has been lovingly hand-crafted, had its lick of paint, and the next step is to get it assembled. We’ve got an exciting plan for that in the new year, which were not going to tell you about just in case we curse it. Watch this space.

Contacts

• Viner www.viner.it

• Velo Solutions www.velosolutions.eu

• Le Beau Velo www.lebeauvelo.co.uk

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- Sriracha 0 sec ago

Shimano were castigated for not bringing on new factories to meet pandemic demand, thus gumming up the supply chain. Their argument at the time was...

- Romanp 9 min 49 sec ago

I figured out a reason of that squeaking noise. I have xpresso 2 and 7, and also xpro 10 pedals, and that squeaking isn't present only at Xpresso 2...

- Dunnoeither 24 min 37 sec ago

There’s one other big reason we’re not going to fly to launches from now on: the world IS in the middle of a man-made climate emergency so taking...

- ktache 33 min 54 sec ago

Surely some nice bright colours, some stripes, it is the seaside. Like beach huts...

- MichaelWinnerRIP 1 hour 10 min ago

Italian tourist and pussycat in Portugal.

- Backladder 1 hour 26 min ago

Am I the only one who thinks the brake levers look awful too?

- David9694 1 hour 58 min ago

Yep, it's official - reds under the, er, bonnet...

- Rendel Harris 2 hours 37 min ago

Indeed, I was drawing from personal experience – I don't use it that often but it's such a nice bit of infrastructure that I sometimes go out of my...

- paulgardener@gmail.com 2 hours 41 min ago

Except socialism doesn't work like that in real life. It's the capitals countries that try to look after those in need, and the average person's...

- KDee 3 hours 39 min ago

It's the mass that's the issue. Two people on a petrol powered scooter can really mess up a cyclist. Also the fact so many of the petrol scooters...

Add new comment

7 comments

This is how bikes should be made. In my youth, the mark of a true cylist was his custom made frame. The mass produces frame was the mark of the beginner. The UK had a proliferation of high quality frame builders, most of whom produced beautiful, hand-made to measure frames. It was noticeale that when a particular 'marque' began to produce in 'industrial' quantities, the quality would deteriorate.

In those days, Viner produced beautiful, hand-made steel frames!

Just ordered a Maxima RS for a client. I am so excited for it to arrive.

I feel like this is the ultimate bike.

I have a Viner Optima (predecessor to Maxima)and a Maxima; both are simply THE best bikes Ive ever ridden. I am a 'large rider' with primarily a track and crit sprinter. Ive owned nearly every professional bike available, each having their own qualities and deficits. Prior to Viner, I owned one high end 'colorful' Italian carbon bike would not track straight in a sprint under power...alum bikes would sprint but be harsh over distance. I discovered the Viners and had a custom build produced; words do not do it justice. The Viner brings together EVERY quality a cyclist would want...comfort, tracking, and performance...unlike ANYTHING I had ever owned in decades of competitive cycling. It feels a part of me when riding...cornering, climbing, decending, and accelerating...all exceptional. Viner, with 'their' decades of expertise have perfected the bike. Beauty, performance, unique...and ALL made in Italy! By the way, Ive seen other 'quality' carbon, and alum, frames break...not made in Italy, not with the commitment to quality that the Viner delivers.

It's refreshing to see how a bike is being made especially when it's been done properly like this. There are far too many monocoque frames from the far east on the market from the bigger brands that cost almost as much as maxima rs but are nowhere near the quality or performance that viner are producing. Well done to Road cc for highlighting a true bike brand with integrity.

Since i ride 20k+km each year on the various routes of the Pro tours i feel that carbon is not the safest material to survive the hardships that a frame has to suffer. ondriest gave me a carbon frame in 2005 and regretably the frame cracked behind the botton bracket, during the TDF , survived the vuelta and to the worlds but when returned to the factory did not return to me. Since then two seasons of a black Allez and then the Pink Fondriest in 2009 & 2010.

Wonder how my porsche carbon and Fuji carbon would survive being tossed around by the TDF gestapo thugs or the airline baggage mafia ?

I would as bold as to say the Viner Maxima is the strongest frame on the road today. It is by far and away the strongest carbon frame made, it will even give the strongest and heaviest steel frame a hard time.

How do we know this?

Well apart from how it feels when you ride one down an mountain decent at 100kph, hard on the brakes and dive into a hairpin apex as if you are riding on rails.

Or the feedback from some "big" customers we have made Maxima's for, who challenged us to build a frame [we engineer the strength of the frame based on the profile of the rider] for them that would last longer than the average 6 months most frames seem to last them. A combination of weight, large frame size and above all high power output can play havoc on most moulded Monocoque frames.

Or accelerated lifecycle test [part of the EN testing procedure] not only does the frame pass with flying colours it ends the test in perfect track and geometry, not even out by 0.1mm

Or the destruction test, a test to see what happens when the frame breaks under serve impact [it is important to study the effect on the rider in the event of a bad accident, the rider could be possibly harmed by their own bike] only problem was the Maxima did not break! I think it is the only bike to not break under this test, and amazingly it was only 0.2mm out of alignment!!

Skippy if you wanted to ride all 3 tours, for many years in a row, the Maxima would get you from start to finish no problem.

Brian at Viner also converts lofts.

Get a loft conversion and Viner thrown in for free?????

Probably not, but worth a try.